Polyimide-Coated Fiber Description

Polyimide-Coated Fiber is an ultra-high-performance fiber optic with a polyimide outer coating that has excellent thermal stability, mechanical strength, and chemical resistance. Polyimide is an ultra-high-performance polymer that can withstand temperatures up to 400°C with a long-term operating temperature of -190℃ to 380℃, so the fiber will be perfectly suited for extreme environments.

Key Features

- High-Temperature Stability: Robust operation under continuous exposure at elevated temperatures up to 300°C, and transient exposure up to 400°C.

- Radiation Stability: Resistant to optical and mechanical degradation under radiation environments.

- Chemical Stability: Resistant to acids, solvents, and corrosive chemicals.

- Excellent Mechanical Properties: Excellent tensile strength and good coating integrity under thermal and mechanical stresses.

Polyimide-Coated Fiber Applications

- Fiber Optic Sensing: Temperature, pressure, and strain sensing in hostile environments

- Aerospace: Data transmission with high-temperature stability

- Oil & Gas: Downhole and pipeline sensing applications

- Medical: Interventional procedures in difficult environments

Polyimide-Coated Fiber Packaging

Our products are wrapped in customized cartons of varying capacities based on the size of the material. Small materials are wrapped separately in PP boxes, whereas large materials are wrapped in customized wooden crates. We follow strict adherence to packaging personalization and the use of appropriate cushioning material for maximum protection while sending.

Packaging: Carton, Wooden box, Paper barrel, Iron barrel, or customized.

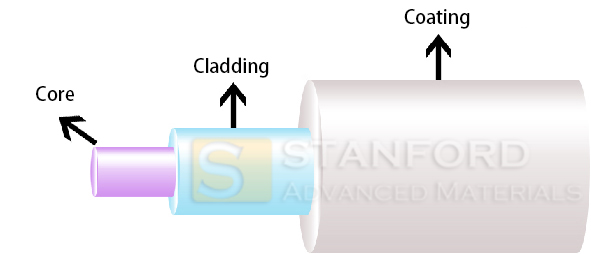

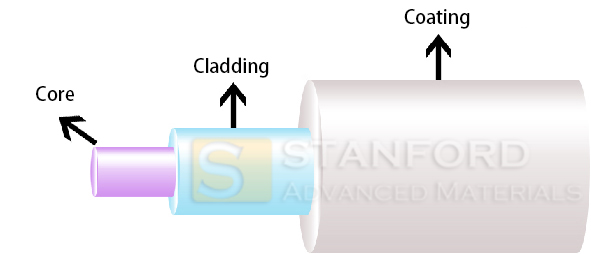

Structure of Optical Fiber

Customization Options

We offer special core sizes, numerical apertures, coatings, and connector configurations to fit your specific system requirements. Square core fiber-optic products can be designed to order to specifications. Test samples only.

|

Parameter

|

Specification

|

|

Spectral Range

|

190 - 1100 nm

|

|

Numerical Aperture (NA)

|

0.22

|

|

Concentricity Deviation (μm)

|

≤ 30

|

|

Core Non-Circularity (%)

|

≤ 2

|

|

Cladding Non-Circularity (%)

|

≤ 2

|

|

Operating Temperature (℃)

|

–190 to +380

|

|

Proof Test Strength (kpsi)

|

100

|

|

Core Material

|

Pure Fused Silica

|

|

Cladding Material

|

Fluorine-Doped Silica Glass

|

|

Coating Material

|

Polyimide Coating

|

|

RoHS Compliance

|

Compliant

|

|

REACH Compliance

|

Compliant

|

Specification

|

Specification

|

Core (μm)

|

Cladding (μm)

|

Coating (μm)

|

|

F_AS 100110 UV PI

|

100

|

110

|

120

|

|

F_AS 200220 UV PI

|

200

|

220

|

235

|

|

F_AS 300330 UV PI

|

300

|

330

|

345

|

|

F_AS 400440 UV PI

|

400

|

440

|

460

|

|

F_AS 600660 UV PI

|

600

|

660

|

680

|

|

F_GI 62.5/125 IR PI

|

62.5

|

125

|

145

|

|

F_AS 105125 IR PI

|

105

|

125

|

145

|

|

F_AS 100140 IR PI

|

100

|

140

|

160

|

|

F_AS 200220 IR PI

|

200

|

220

|

240

|

|

F_AS 200280 IR PI

|

200

|

280

|

300

|

|

F_AS 300330 IR PI

|

300

|

330

|

365

|

|

F_AS 400440 IR PI

|

400

|

440

|

470

|

|

F_AS 600660 IR PI

|

600

|

660

|

690

|

|

F_AS 10001100 IR PI

|

1000

|

1100

|

1150

|

*The above product information is based on theoretical data. For specific requirements and detailed inquiries, please contact us.

Get a Quote

Get a Quote