Description

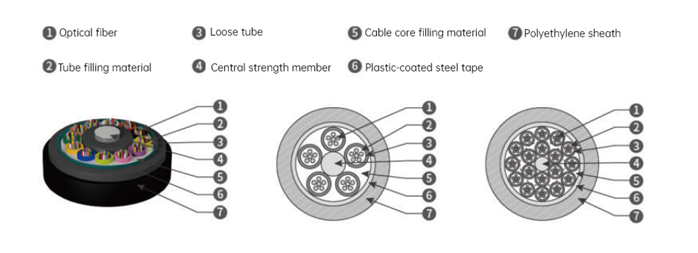

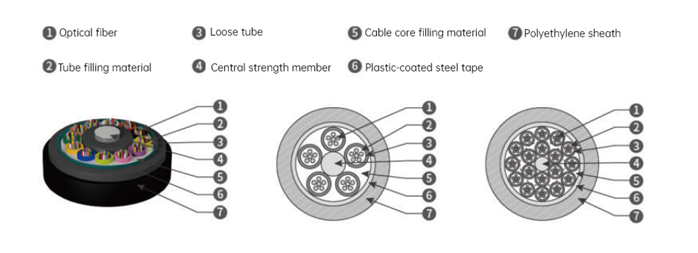

The GYTS optical cable is applied to outdoor use requiring water resistance, mechanical stability, and lightness. The colored optical fibers are placed in high-modulus, hydrolysis-resistant loose tubes greased with thixotropic water-blocking gel for effective fiber protection against water and stress.

For added resistance to water, the loose tubes are water-blocking material coated externally, giving great longitudinal protection. Tensile strength and structural integrity are provided by two parallel steel wires on the sides of the cable. A polyethylene (PE) sheath finishes the cable, offering rugged protection against environmental exposure.

Feature

Cross-section Diagram

- Hydrolysis-Resistant Loose Tube: Maintains mechanical strength and protects fibers from moisture over long periods.

- Thixotropic Gel Filling: Seals and protects optical fibers from moisture completely and stably.

- UV-Resistant PE Sheath: Extends service life under sunlight exposure for a long time.

- Central Steel Wire: Strengthens tensile strength and structural stability.

- Double-Sided Plastic-Coated Steel Tape (PSP): Improves moisture resistance and cable structure strength as a whole.

- Stable Mechanical and Temperature Performance: Functions well under mechanical stress and within a wide temperature range.

Application Scenario

- Duct Installations: Compact and light design allows for easy handling and cost-effective installation over long distances.

- Suburban and Rural Networks: Suitable for communication networks in moderate environmental demand regions.

- High-Moisture or Humid Areas: Provides stable performance in regions with high rainfall frequency, high humidity, or near water bodies.

- Backbone Communication Networks: Reliable for long-distance data communication in outdoor backbone lines.

- Low Mechanical Stress Areas: Applicable in stable grounds or areas with no heavy machinery influence.

- Temporary or Quick Deployment: Light, flexible construction enables quick installation for temporary networks.

- Industrial and Utility Networks: Can be used in industrial or utility settings where moisture resistance is required but not complete armor protection.

The GYTS light-armored cable offers a blend of strength, water resistance, and ease of installation to address a wide range of outdoor network applications.

Optical Characteristics

|

Fiber Type

|

G.652

|

G.655

|

50/125μm

|

62.5/125μm

|

|

Attenuation

(±20℃)

|

@850nm

|

-

|

-

|

≤3.0 dB/km

|

≤3.3 dB/km

|

|

@1300nm

|

-

|

-

|

≤1.0 dB/km

|

≤1.0 dB/km

|

|

@1310nm

|

≤0.36 dB/km

|

≤0.40 dB/km

|

-

|

-

|

|

@1550nm

|

≤0.22 dB/km

|

≤0.23dB/km

|

-

|

-

|

|

Bandwidth

(Class A)

|

@850nm

|

-

|

-

|

≥500 MHz·km

|

≥200 MHz·km

|

|

@1300nm

|

-

|

-

|

≥500 MHz·km

|

≥500 MHz·km

|

|

Numerical Aperture

|

-

|

-

|

0.200±0.015NA

|

0.275±0.015NS

|

|

Cable Cut-off Wavelength λcc

|

≤1260nm

|

≤1450nm

|

-

|

-

|

Technical Parameters

|

Type

|

Fiber Count

|

Loose Tubes

|

Filling Ropes

|

Cable Weight

Kg/km

|

Tensile Strength

Long/short term

N

|

Crush Force

Long/short term

N/100mm

|

Bending Radius

Static/Dynamic

mm

|

|

GYTS-2~6Xn

|

2~6

|

1

|

4

|

96

|

600/1500

|

300/1000

|

10D/20D

|

|

GYTS-8~12Xn

|

8~12

|

2

|

3

|

96

|

|

GYTS-14~18Xn

|

14~18

|

3

|

2

|

96

|

|

GYTS-20~24Xn

|

20~24

|

4

|

1

|

96

|

|

GYTS-26~30Xn

|

26~30

|

5

|

0

|

96

|

|

GYTS-32~36Xn

|

32~36

|

6

|

0

|

105

|

|

GYTS-38~48Xn

|

38~48

|

4

|

1

|

111

|

|

GYTS-50~60Xn

|

50~60

|

5

|

0

|

111

|

|

GYTS-62~72Xn

|

62~72

|

6

|

0

|

138

|

|

GYTS-74~84Xn

|

74~84

|

7

|

1

|

168

|

|

GYTS-86~96Xn

|

86~96

|

8

|

0

|

168

|

|

GYTS-98~108Xn

|

98~108

|

9

|

1

|

195

|

|

GYTS-110~120Xn

|

110~120

|

10

|

0

|

195

|

|

GYTS-122~132Xn

|

122~132

|

11

|

1

|

228

|

|

GYTS-134~144Xn

|

134~144

|

12

|

0

|

228

|

|

GYTS-146~216Xn

|

146~216

|

13-18

|

5-0

|

228

|

|

GYTS-288Xn

|

288

|

24

|

0

|

283

|

*Sizes and performance values can be specified by customers.

Get a Quote

Get a Quote