Description

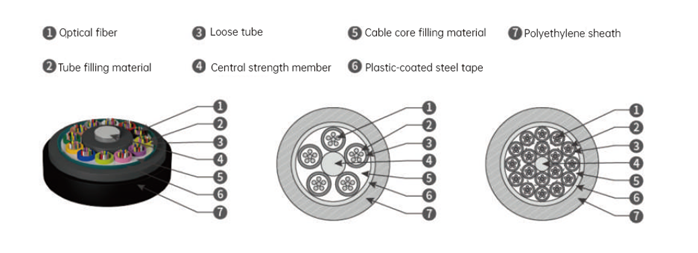

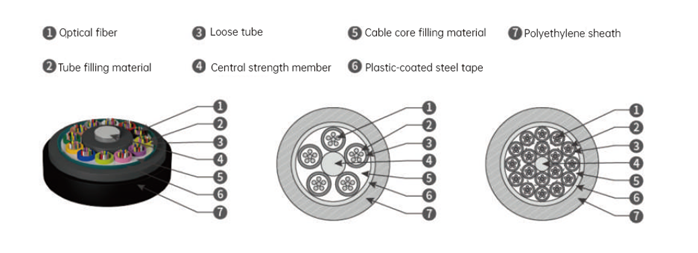

Loose Tube Layer Stranded Non-armored Optical Cable is a versatile, high-performance solution designed for outdoor applications requiring robust water resistance and reliable mechanical strength. Colored optical fibers are housed in loose tubes made from high-modulus material, which are filled with thixotropic water-blocking gel to provide superior moisture protection.

A central metal strength member ensures structural stability, while the loose tubes and filling ropes are twisted around it to form a compact, circular cable core. The gaps within the cable core and between the core and aluminum tape are filled with water-blocking gel to ensure longitudinal water resistance. The cable is then longitudinally wrapped with aluminum tape for enhanced moisture protection and finished with a durable polyethylene sheath for environmental resilience.

Feature

Cross-section Diagram

- Hydrolysis-Resistant and High-Strength Loose Tube Material

The loose tube material is highly resistant to hydrolysis and offers exceptional mechanical strength, ensuring long-term durability in various environments.

Provides critical sealing and moisture protection for optical fibers, enhancing their longevity and performance.

The polyethylene sheath delivers excellent protection against ultraviolet radiation, ensuring the cable’s reliability in outdoor applications.

- Central Steel Wire Strength Member

A single steel wire core enhances tensile strength, improves parallel alignment, and provides structural stability during installation and operation.

- Reliable Mechanical and Temperature Performance

Exhibits stable mechanical properties and consistent performance across a wide range of temperatures, suitable for diverse conditions.

- Moisture-Resistant Plastic-Coated Aluminum Tape

The aluminum tape layer effectively blocks moisture ingress, reinforcing the cable’s resistance to water and environmental stresses.

Application Scenario

GYTA Loose Tube Layer Stranded Non-armored Optical Cable is an excellent choice for outdoor duct installations, backbone networks, and high-moisture environments. Its lightweight, water-resistant design makes it a versatile and cost-effective solution for suburban, rural, and urban communication networks requiring moderate mechanical protection.

1. Duct Installations

Ideal for installation in ducts due to its lightweight and compact design, making it easy to handle and deploy over long distances.

2. Suburban and Rural Communication Networks

Perfect for connecting suburban and rural areas, offering a cost-effective and durable solution for backbone and distribution networks.

3. High-Moisture or Humid Environments

The water-blocking gel and aluminum tape provide robust protection against moisture ingress, making it suitable for wet or humid regions, such as areas near rivers, lakes, or wetlands.

4. Backbone Communication Networks

Commonly used in backbone networks due to its ability to support long-distance, high-capacity data transmission.

5. Urban Network Infrastructure

Suitable for urban deployments where moderate mechanical protection is sufficient, such as underground duct systems in cities.

6. Industrial Applications

Can be used in industrial environments requiring stable and reliable optical transmission in moderately demanding conditions.

7. Temporary or Rapid Deployment Projects

Lightweight and easy to install, making it ideal for temporary or rapidly deployed communication networks.

8. Outdoor Areas with Low Mechanical Stress

Best suited for regions where external mechanical stresses, such as heavy traffic or rodent activity, are minimal, as it lacks an armored layer.

Optical Characteristics

|

Fiber Type

|

G.652

|

G.655

|

50/125μm

|

62.5/125μm

|

|

Attenuation

(±20℃)

|

@850nm

|

-

|

-

|

≤3.0 dB/km

|

≤3.3 dB/km

|

|

@1300nm

|

-

|

-

|

≤1.0 dB/km

|

≤1.0 dB/km

|

|

@1310nm

|

≤0.36 dB/km

|

≤0.40 dB/km

|

-

|

-

|

|

@1550nm

|

≤0.22 dB/km

|

≤0.23dB/km

|

-

|

-

|

|

Bandwidth

(Class A)

|

@850nm

|

-

|

-

|

≥500 MHz·km

|

≥200 MHz·km

|

|

@1300nm

|

-

|

-

|

≥500 MHz·km

|

≥500 MHz·km

|

|

Numerical Aperture

|

-

|

-

|

0.200±0.015NA

|

0.275±0.015NS

|

|

Cable Cut-off Wavelength λcc

|

≤1260nm

|

≤1450nm

|

-

|

-

|

Technical Parameters

|

Type

|

Fiber Count

|

Loose Tubes

|

Filling Ropes

|

Cable Weight

Kg/km

|

Tensile Strength

Long/short term

N

|

Crush Force

Long/short term

N/100mm

|

Bending Radius

Static/Dynamic

mm

|

|

GYTA-2~6Xn

|

2~6

|

1

|

4

|

76

|

600/1500

|

300/1000

|

10D/20D

|

|

GYTA-8~12Xn

|

8~12

|

2

|

3

|

76

|

|

GYTA-14~18Xn

|

14~18

|

3

|

2

|

76

|

|

GYTA-20~24Xn

|

20~24

|

4

|

1

|

76

|

|

GYTA-26~30Xn

|

26~30

|

5

|

0

|

76

|

|

GYTA-32~36Xn

|

32~36

|

6

|

0

|

85

|

|

GYTA-38~48Xn

|

38~48

|

4

|

1

|

90

|

|

GYTA-50~60Xn

|

50~60

|

5

|

0

|

90

|

|

GYTA-62~72Xn

|

62~72

|

6

|

0

|

113

|

|

GYTA-74~84Xn

|

74~84

|

7

|

1

|

136

|

|

GYTA-86~96Xn

|

86~96

|

8

|

0

|

136

|

|

GYTA-98~108Xn

|

98~108

|

9

|

1

|

163

|

|

GYTA-110~120Xn

|

110~120

|

10

|

0

|

163

|

|

GYTA-122~132Xn

|

122~132

|

11

|

1

|

190

|

|

GYTA-134~144Xn

|

134~144

|

12

|

0

|

190

|

|

GYTA-146~216Xn

|

146~216

|

13-18

|

5-0

|

190

|

|

GYTA-288Xn

|

288

|

24

|

0

|

239

|

*Sizes and performance values can be specified by customers.

Get a Quote

Get a Quote