Description

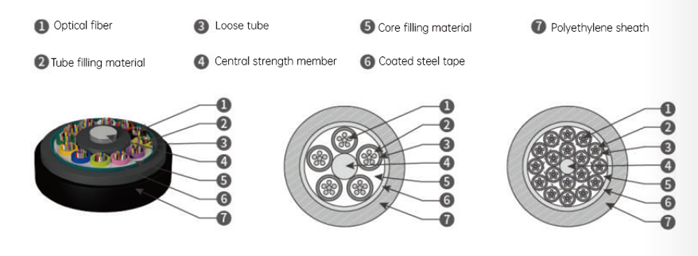

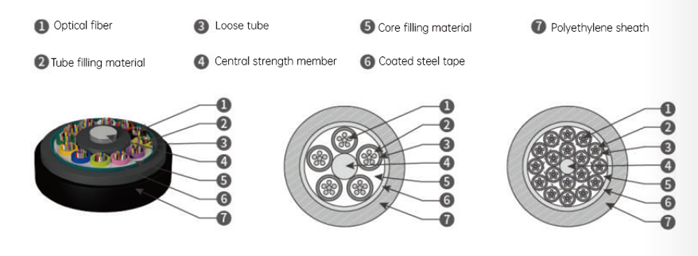

GYFTZA53 outside-plant transmission cable is built for optimal performance and longevity for outdoor communications networks. Colored optical fibers are enclosed in high-modulus thixotropic gel-filled loose tube with excellent sealing and water-blocking capabilities. A non-metallic Fiber Reinforced Plastic (FRP) strength member in the center provides optimal tensile and structural integrity without the hazard of electromagnetic signal degradation.

Loose tube and filler ropes are spirally stranded over the FRP core to form a compact cylindrical structure. Water-blocking gel is used to fill the voids in the cable to improve moisture resistance. An aluminium tape is longitudinally applied over the core and backed by a polyethylene inner sheath. For additional protection from outside factors, double-sided coated steel tape armour offers additional support and develops a strong flame-retardant outside covering to ensure safety and dependability in hazard-prone situations.

This cable is appropriate for harsh outdoor use where flame resistance, good moisture resistance, and high mechanical performance are required.

Feature

Cross-section Diagram

Hydrolysis-Resistant Loose Tube Material: Having been manufactured from high-modulus material, loose tube offers great resistance to hydrolysis and long-term mechanical strength.

Thixotropic Gel Filling: It is filled with thixotropic gel that offers good water-blocking protection to prevent moisture injury to the Optical Fibers.

Flame-Retardant Sheath Material: This outer covering is constructed out of flame-retardent material in order to meet fire safety standards particularly in high hazard situations.

Non-Metallic Central Reinforcing Core (FRP): FRP core provides enhanced tensile strength and structural integrity and removes electromagnetic interference and is ideal for sensitive applications.

Exceptional Temperature and Mechanical Performance: Engineered to work effectively under mechanical stress and harsh weather conditions, it's compatible for any kind of outdoor environment.

Moisture-Resistant Aluminum Tape Coating: Longitudinally wound coated aluminium tape provides good moisture resistance and also makes the cable more durable in wet or damp environments.

Double-Sided Corrugated Steel Tape (PSP) Armor: Double-coated steel tape armor shields the cable from mechanical harm and moisture intrusion and provides reliability in harsh environments.

Application Scenario

Urban Communication Networks: Perfect for distribution and backbone networks in cities, where fire safety is paramount. Ideal for cities with high usage. The cable's flame-retardant covering and high longevity suit cities best.

Industrial sites: Ideal for use in areas such as factories, refineries, plants where fire hazard, high humidity levels, and mechanical stress are typical.

Subterranean Duct Install: This cable is intended for installation in below ground ducts and offers good resistance to moisture ingression by virtue of its gel fill and aluminium tape wrapping.

Tunnel and Subway Systems: Best suited for tunnels, subways, and other confined spaces, the GYFTZA53 offers reliable comms as it meets fire safety standards in high hazard situations.

Coastal and High-Humidity Locations: This cable performs best in wet locations with high rainfall, high humidity, or exposure to the coast due to good resistance to moisture and corrosion.

Aerial Deployments: Light in weight and strong, the GYFTZA53 is ideal for overhead cable applications where the non-metallic FRP core offers electromagnetic interference rejection.

Critical Infrastructure Projects: Intrinsic in intelligent city infrastructure, traffic centers, emergency networks, and other applications where high reliability, flame resistance, and long use are essential.

Distant and Rural Networks: Ideal for long-distance communications in such remote or rural locations as this provides a robust, dependable solution capable of operating through harsh environmental conditions.

Optical Characteristics

|

Fiber Type

|

G.652

|

G.655

|

50/125μm

|

62.5/125μm

|

|

Attenuation

(±20℃)

|

@850nm

|

-

|

-

|

≤3.3 dB/km

|

≤3.5 dB/km

|

|

@1300nm

|

-

|

-

|

≤1.2 dB/km

|

≤1.2 dB/km

|

|

@1310nm

|

≤0.36 dB/km

|

≤0.40 dB/km

|

-

|

-

|

|

@1550nm

|

≤0.22 dB/km

|

≤0.23dB/km

|

-

|

-

|

|

Bandwidth

(Class A)

|

@850nm

|

-

|

-

|

≥500 MHz·km

|

≥200 MHz·km

|

|

@1300nm

|

-

|

-

|

≥500 MHz·km

|

≥500 MHz·km

|

|

Numerical Aperture

|

-

|

-

|

0.200±0.015NA

|

0.275±0.015NS

|

|

Cable Cut-off Wavelength λcc

|

≤1260nm

|

≤1450nm

|

-

|

-

|

Technical Parameters

|

Type

|

Fiber Count

|

Loose Tubes

|

Filling Ropes

|

Cable Weight

Kg/km

|

Tensile strength

Long/short term

N

|

Crush

Long/short term

N/100mm

|

Bending Radius

Static/Dynamic

mm

|

|

GYFTZA53-2~6Xn

|

2~6

|

1

|

7

|

275

|

1000/3000

|

1000/3000

|

12.5D/25D

|

|

GYFTZA53-8~12Xn

|

8~12

|

2

|

6

|

275

|

|

GYFTZA53-14~18Xn

|

14~18

|

3

|

5

|

275

|

|

GYFTZA53-20~24Xn

|

20~24

|

4

|

4

|

275

|

|

GYFTZA53-26~30Xn

|

26~30

|

5

|

3

|

275

|

|

GYFTZA53-32~36Xn

|

32~36

|

6

|

2

|

275

|

|

GYFTZA53-38~42Xn

|

38~42

|

7

|

1

|

275

|

|

GYFTZA53-44~48Xn

|

44~48

|

8

|

0

|

275

|

|

GYFTZA53-50~60Xn

|

50~60

|

5

|

3

|

290

|

|

GYFTZA53-62~72Xn

|

62~72

|

6

|

2

|

290

|

|

GYFTZA53-74~84Xn

|

74~84

|

7

|

1

|

290

|

|

GYFTZA53-86~96Xn

|

86~96

|

8

|

0

|

290

|

|

GYFTZA53-98~108Xn

|

98~108

|

9

|

1

|

327

|

|

GYFTZA53-110~120Xn

|

110~120

|

10

|

0

|

327

|

|

GYFTZA53-122~132Xn

|

122~132

|

11

|

1

|

384

|

|

GYFTZA53-134~144Xn

|

134~144

|

12

|

0

|

384

|

*Sizes and performance values can be specified by customers.

Get a Quote

Get a Quote