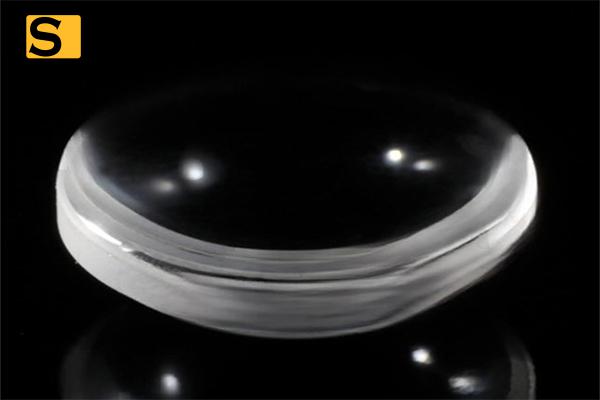

Plano-Convex Lenses – Description

Plano-convex lenses are optical components featuring one flat surface and one outward-curved (convex) surface. This geometry makes them ideal for focusing parallel light to a single point or collimating diverging light into a parallel beam. They are widely used in laser optics, imaging systems, projection equipment, and scientific instruments.

The flat surface allows for easy mounting, while the curved side ensures precise light manipulation. These lenses are typically manufactured from high-grade materials like BK7, K9, fused silica, quartz, or sapphire, offering excellent transmission, low wavefront distortion, and high durability. Coatings such as anti-reflective (AR) or UV/IR protective layers can be applied based on application needs.

Applications of Plano-Convex Lenses

· Laser Systems

Focus or collimate laser beams for applications like cutting, engraving, alignment, and medical lasers.

· Imaging Optics

Used in cameras, sensors, microscopes, and telescopic systems to focus light onto detectors or film.

· Optical Instruments

Enhance image clarity and light control in telescopes, binoculars, spectrometers, and collimators.

· Projection Systems

Direct and focus light onto display surfaces in digital and optical projection setups.

· Microscopy

Focus illumination precisely onto samples for high-resolution imaging.

· Beam Shaping

Convert divergent beams into collimated light or shape beam profiles in industrial and research optics.

· Optical Communication

Serve in fiber coupling and collimation setups to manage light entering or exiting fiber-optic systems.

Packaging

Plano-convex lenses are securely packed based on size and material:

-

Small items: Individually sealed in PP boxes with protective padding.

-

Medium to large items: Custom-fit cartons or foam-lined wooden crates.

-

Custom options: Carton, wooden box, paper barrel, or iron barrel available upon request.

Each package is designed to prevent vibration, scratching, or temperature-induced stress during transit.

Manufacturing Process

-

Material Selection

Optical-grade BK7, K9, fused silica, sapphire, or quartz is selected based on transmission range, thermal properties, and mechanical strength.

-

Cutting & Shaping

Material is cut to size using precision saws, then shaped into rough blanks.

-

Grinding

Curved and flat surfaces are ground to achieve precise radii and plano-flatness.

-

Polishing

Surfaces are polished to high clarity and minimal surface error (up to λ/10).

-

Coating (Optional)

AR or specialty coatings (UV, IR, broadband) are applied for enhanced performance.

-

Inspection

Each lens is tested for surface quality, focal length accuracy, centering, and optical flatness.

-

Edge Finishing

Lens edges are beveled (e.g., <0.2 × 4.5°) to reduce chipping and ease mounting.

-

Final Packaging

Lenses are cleaned, verified, and packed with moisture and shock protection.

Additional Notes

-

Standard Coating Range: 400–700 nm for visible AR coating.

-

UV Applications: Quartz or fused silica substrates with UV AR coatings enable deep-UV transmission.

-

Custom Options: Diameter, thickness, focal length, and coatings can be tailored for specific applications.

Material Performance Comparison

| Property |

K9 Glass |

Quartz |

Fused Silica |

BK7 |

Sapphire |

| Transmission Range |

300–2500 nm |

170–2500 nm |

160–2500 nm |

300–2500 nm |

200–5000 nm |

| Refractive Index (nd) |

1.515 |

1.46 |

1.46 |

1.515 |

1.77 |

| Abbe Number |

64.17 |

73.8 |

73.8 |

64.2 |

72 |

| Thermal Expansion (×10⁻⁶) |

7.1 |

0.55 |

0.55 |

7.1 |

5.6 |

| Density (g/cm³) |

2.52 |

2.2 |

2.2 |

2.51 |

3.98 |

| Hardness (Mohs) |

6 |

7 |

7 |

6 |

9 |

| Melting Point (℃) |

720 |

1650 |

1723 |

820 |

2030 |

| Common Uses |

General optics |

UV, spectroscopy |

UV lasers |

Standard optics |

High-durability optics |

Get a Quote

Get a Quote