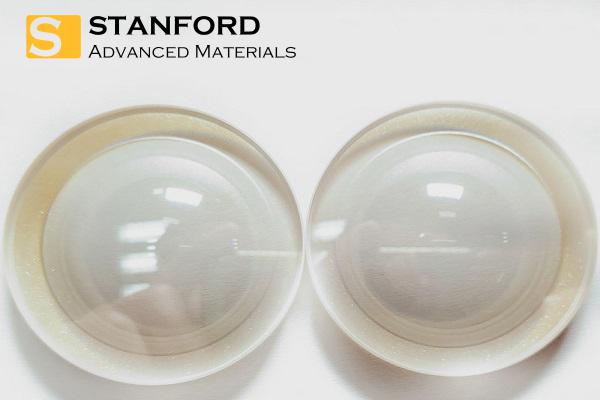

Zinc Sulfide (ZnS) Wafer Description

Zinc Sulfide (ZnS) is an inorganic compound with the chemical formula ZnS, characterized by high purity and water insolubility. ZnS is an excellent infrared optical window material, featuring a uniform refractive index and consistent quality. It provides strong transmission in the 8 to 12 μm wavelength range. Multispectral ZnS can serve as a carrier material for 8 to 12 μm and as a window material for 3 to 5 μm wavelengths. Compared to Zinc Selenide (ZnSe), ZnS is more cost-effective, harder, and has twice the breaking strength, making it suitable for harsh environments such as missile housings and military aircraft infrared windows.

Zinc Sulfide (ZnS) Wafer Applications

-

Infrared Detectors and Windows: Used for high-performance infrared detectors and windows, especially in the 8 to 12 μm range.

-

Optical Coatings: Applied as coatings on infrared and visible optical components to enhance durability and performance.

-

Infrared Imaging Sensors: Utilized in thermal imaging and night vision sensor technologies.

-

Ultraviolet Detectors and Laser Devices: Functions as a substrate in UV detection and laser systems.

-

Scintillation Detector Substrates: Serves as a base material in ZnS-based scintillation detectors for radiation detection.

-

Military and Aerospace: Due to its hardness and strength, ZnS wafers are employed in demanding environments such as missile casings and military aircraft infrared windows.

Packaging and Handling

Our ZnS wafers are carefully handled during storage and transportation to preserve their original quality and performance.

With its excellent optical properties, durability, and cost advantages over similar materials, Zinc Sulfide wafers are an ideal choice for a wide range of infrared and multispectral optical applications.

Get a Quote

Get a Quote