.jpg)

Applications and Advantages of ADSS Optical Cable in Fiber Communication

In power line corridors, mountain passes, or rural broadband rollouts, engineers often face the same question: how to route fiber from point A to point B without building a whole new support system? That is where ADSS – short for All-Dielectric Self-Supporting – cable has been earning its keep for decades. It's not just another aerial fiber; its design solves problems that metallic cables simply can't.

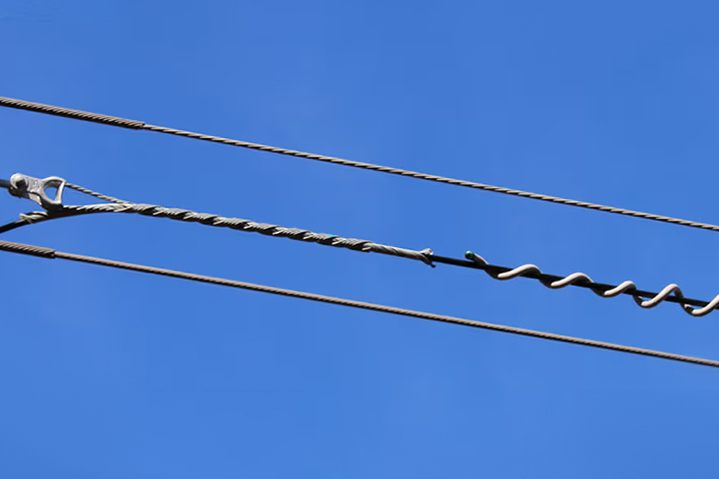

Built to Carry Its Own Weight

The self-supporting idea is literal here. Instead of a steel messenger wire, the strength comes from high-strength para-aramid fibers running inside the jacket. No steel means no induced voltages when hung next to 220 kV or 500 kV lines.

This also simplifies permitting. In many regions in the United States, using a non-conductive cable avoids extra grounding hardware and the engineering review that comes with it. For utility companies, that's weeks off the project schedule.

Jacket and Fiber Choices Matter

Most outdoor ADSS today uses either UV-stabilized polyethylene or a track-resistant (TR) outer layer. The TR versions are critical if the cable will run within 10 m of high-voltage conductors; otherwise, electrical tracking from corona discharge can slowly eat away at the surface.

Inside, the fibers are usually ITU-T G.652D single-mode. Expect attenuation figures of around 0.35 dB/km at 1310 nm. Not lab-perfect, but well within spec for 60–80 km runs without repeaters. In a cold-climate install in rural Alaska, I've seen PE-jacketed ADSS stay flexible at –35 °C — though installers still wore heated gloves.

Adaptable to Terrain and Weather

One reason crews like ADSS is that it's lightweight enough to tension by hand on short spans, yet tough enough for 1,000+ m runs with proper hardware. That means it works on flat farmland, over river crossings, or zig-zagging through forest.

It also holds up in lightning-prone regions, where metallic support cables would require surge protection at every splice point. In coastal areas like Florida, the absence of steel removes the worry about salt-fog corrosion. I've seen 15-year-old ADSS in California still testing at near-original tensile strength.

Transmission Reliability

In service, these cables behave like any high-quality single-mode route: low loss, low dispersion, and high bandwidth headroom. The big difference is what's not happening — there's no galvanic corrosion, no voltage induction, and far fewer maintenance call-outs.

Fiber counts vary; you might see a 48-core build for rural broadband or 144 cores for a regional backbone. Once it's up, there is usually little reason to touch it until an expansion or a storm takes out the pole itself.

Not the Cheapest Per Meter — But Often Cheaper Overall

ADSS cable can look pricey on a per-meter basis compared to steel-reinforced aerial fiber. But factor in no messenger wire, fewer fittings, and faster stringing, and total installed cost often comes out even — or lower — especially when the span count is high. For utilities piggybacking on transmission towers, the savings in labor and downtime are obvious.

Manufacturers who build to IEC 60794 test these cables under tension, bending, and temperature cycling before they leave the factory. If you're sourcing for a project, that certification is worth checking; it's the difference between a 20-year asset and a headache in year five.

Closing Note

ADSS isn't new, but its combination of dielectric safety, structural strength, and environmental toughness keeps it relevant — from smart-grid fiber networks to long-haul telecom backbones. For teams planning new aerial routes, it's worth putting on the shortlist.

If you're evaluating ADSS options or need matching fiber hardware, Stanford Optics can supply both the cable and accessories, along with technical support to ensure the design fits your route and load conditions. In fiber work, the right material choice at the start saves years of trouble later.