Armored vs. Unarmored Cable Solutions for Reliable Data Transmission

Introduction

Fiber patch cords sit at the core of modern data networks. Choosing the proper type is key to long-term network stability. Yet, it can be confusing when you must decide between armored and unarmored fiber patch cords.

Understanding Armored and Unarmored Fiber Optic Patchcords

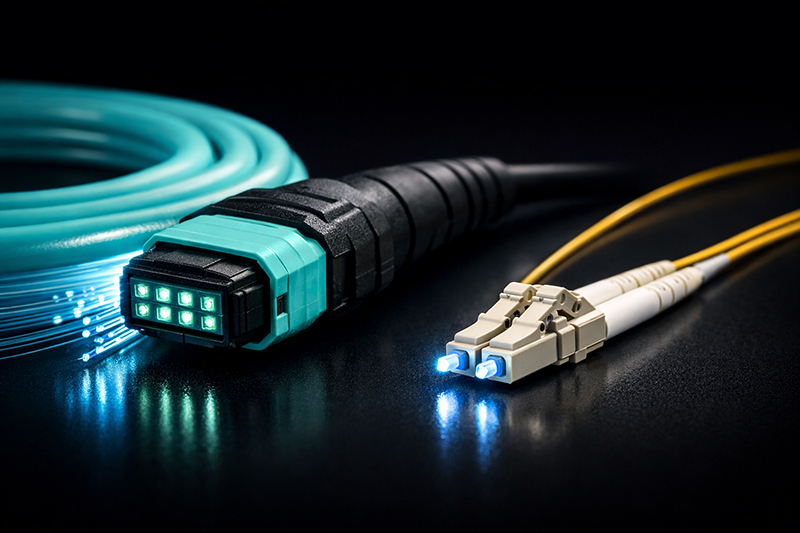

Fiber optic patch cords come in two main types: armored and unarmored. The major difference lies in the level of physical protection they offer.

Armored fiber optic patch cords are built with a metal layer—often steel or aluminum—that wraps around the fiber. This extra shield helps the patchcord resist impacts, heavy pressures, and even animal damage. It can stand up to harsh weather and tough industrial settings. In many outdoor or underground installations, the armored cord is the safe choice. Although the initial price is higher, the robust protection usually pays off over time by reducing repair and replacement costs.

On the other hand, unarmored fiber optical patch cords use only a durable outer jacket made of materials like LSZH, PVC, or OFNP. They are lighter and more flexible than their armored kin. This type is ideal for indoor settings or controlled outdoor environments. In places like office complexes or data centers, where physical risks are lower, their ease of installation and lower cost make them an attractive option.

Choosing the Right Fiber Optic Patchcord

When deciding between armored and unarmored patch cords, consider the physical conditions of your installation area.

If your work is set in an indoor environment or a place where there is little chance of physical harm, an unarmored patch cord can be a good fit. They are light, easy to handle, and not too expensive. Many users find that the flexibility of unarmored cords saves both time and labor during setup. For example, in data centers that are free from heavy machinery or rodents, unarmored cords can be a cost-effective and practical choice.

In contrast, armored patch cords are necessary for tougher surroundings. Think of locations with heavy equipment operations, outdoor installations exposed to weather extremes, or underground cables where soil pressure is a concern. In these cases, the metal casing provides that extra security. It prevents accidental damage from impact or crushing and cuts down on the risk of fiber breaks. Industries such as manufacturing or energy production may benefit from armored cords to keep their networks reliable under stress.

It helps to review your project's requirements. List the potential threats—whether from physical impacts, rodent activity, or environmental extremes. With that list in hand, you can determine if the extra cost of an armored cord is justified. Sometimes, spending a bit more upfront can mean fewer headaches and lower maintenance costs later on.

Real-World Applications and Considerations

Consider a bustling office building with well-controlled environmental conditions. Unarmored fiber patch cords work well here because they are easier to route through narrow cable trays and require less effort during installation. The protected yet flexible design meets standard corporate requirements without the need for heavy-duty features.

Now, imagine a rugged industrial facility where equipment may bump into cables or where cables might be exposed to harsh weather. For such settings, armored fiber patch cords are a better match. The metal layer can handle impacts and prevent damage from accidental harsh treatment. In many industrial cases, network downtime is not an option, and the reliability of armored cords can be crucial.

There are also mixed cases. In some outdoor installations where cable runs pass through both protected areas and more exposed environments, it might be wise to use armored patch cords in the vulnerable sections while saving costs with unarmored sections where conditions are milder.

Conclusion

In summary, your choice between armored and unarmored fiber optic patch cords depends on your specific installation needs, budget, and the physical challenges of your environment. If safety and durability are essential due to rough environmental conditions, an armored patch cord stands out as the reliable choice. Meanwhile, for controlled settings where ease of installation and cost savings are important, an unarmored patch cord can do the job well.

At the end of the day, both options have their merits. We encourage you to evaluate your working conditions carefully to decide which option fits best into your project. For high quality fiber optic patch cords, look no further than Stanford Optics, your trusted materials supplier.