Underground Installation of ADSS Cable: Evaluation and Insights

Introduction

The question of whether ADSS (All-Dielectric Self-Supporting) cable should be installed below ground level has sparked many debates among professionals. In simpler words, can a cable made without metal supports work well when buried? This paper offers a practical discussion on the topic, sharing insights from years of hands-on experience in the field.

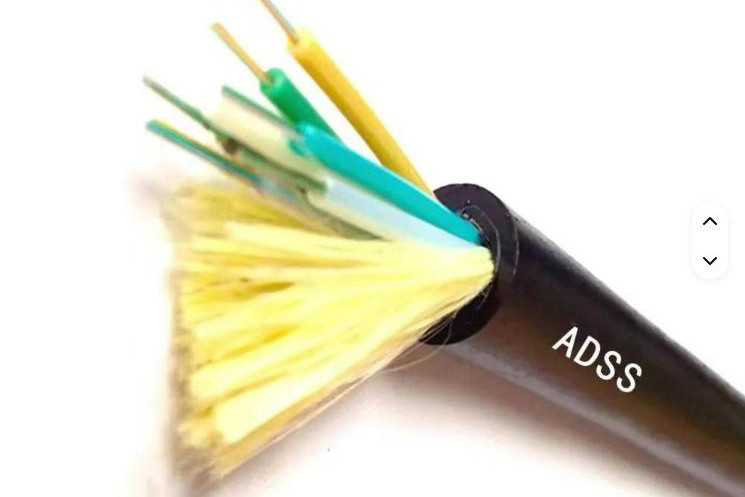

Below is an image that shows an ADSS cable in its typical form.

Understanding ADSS Fiber Optic Cable

ADSS fiber optic cable is built to stand on its own. It does not require a separate metal support, a feature that makes it popular in outdoor installations. These cables use non-conductive materials to hold them in place when strung between poles or along power lines. Such a design helps to reduce any risk of electrical interference when placed near high voltage lines.

Being naturally less prone to conduction issues, ADSS cables provide a viable solution for settings where electrical safety is a priority. Their design ensures fewer complications during installation in overhead settings. However, when it comes to underground installation, different factors need to be taken into account.

The Pros and Cons of Underground Installation of ADSS Cable

When considering underground installation, there are several advantages and challenges to weigh.

Pros

• Reduced Exposure to Weather: Burying the cable spares it from harsh winds, ice storms, and even lightning. In regular conditions, these external factors can shorten the life of a cable. Below ground, there is less threat from unpredictable weather.

• Aesthetic Appeal: In places where the look of your surroundings matters, removing visible cables can improve the overall appearance of the area. Cities and neighborhoods sometimes choose underground installation simply to keep the environment neat.

• Lower Risk of Physical Damage: Cables on the surface are often subject to accidents caused by construction, vehicles, or even fallen branches. Underground installation lowers the risk of such damage, saving repair costs over time.

Cons

• Complexity and Cost: Digging trenches and laying cables underground is not an easy job. It demands proper planning along with higher travel and labor expenses. In areas with rocky or very hard soil, costs can climb even more due to the additional work required.

• Maintenance and Repair Challenges: Should the cable experience a break or fault, locating that problem is more challenging when the cable is below ground. Special equipment may be necessary, and any repair work might mean reopening the ground along the cable’s route. This can cause delays and inconvenience.

• Moisture and Corrosion Risks: The underground environment is naturally humid, which increases the risk of corrosion and moisture damage. In such cases, extra protective measures such as waterproof coatings must be used. These extra layers add to the overall complexity and cost of the project.

Considerations for Underground Installation of ADSS Cables

If the underground route is selected, a few thoughtful steps must be taken to ensure success.

Cable Selection

Not all ADSS cables are equal for underground use. Some are built with features that resist moisture and corrosion better than others. Do your due diligence and choose a cable that is rated for underground use. Search for proper industry standards and choices that are designed to manage extra moisture and pressure from the ground.

Installation Standards and Practices

The devil is in the details. Digging deep enough to protect the cable but not so deep that future maintenance becomes problematic can be a balancing act. The cable must have good bedding material and will be well backfilled. A protective conduit is usually used to give extra protection to the cable from potential damage, i.e., from burrowing animals or loose water. Following stipulated guidelines and safety protocols ensures the cable is accessible for any repair that might be necessary and lasts forever.

Environmental Impact Assessment

Before the initial groundbreaking shovel, it is wise to take the environmental factor into consideration. For areas that are wildlife-rich or have sensitive ecosystems, an analysis is a wise notion. This study can ascertain means of avoiding disturbance to the soil structure or groundwater patterns. This guarantees that the installation meets local standards and does not disrupt the balance of nature.

Practical Examples and Common Cases

In many rural and suburban locations, underground fiber optic networks have been successfully implemented. For instance, a community network in a moderate climate area chose to bury its cables. The result was fewer interruptions in service during heavy storms or strong winds. In a similar case, a municipal project replaced aging aerial cables with underground installations. The reduction in repair calls was significant, thanks to the protection offered by the soil.

Another situation to consider is where cables pass through public parks. In these spaces, aesthetics and safety matter a great deal. Burying the cables kept the environment clean and free of visible clutter. Even in areas prone to construction, well-planned underground routes have been shown to lower long-term maintenance expenses, despite the higher initial investment.

Conclusion

ADSS fiber optic cables have already demonstrated their worth in overhead installations, but they can also find a niche underground in certain situations. As we've mentioned, the benefits are longer life, improved appearance, and less physical damage. But the difficulties in installation and maintenance cannot be ignored.

It is essential to choose the right cable, follow rigorous installation practices, and have an accurate assessment of environmental conditions before burying such cables. If well planned and executed, underground installations will deliver stable and long-term performance.

For further guidance or assistance in selecting the right materials, consider reaching out to Stanford Optics. They are known for their expertise and quality supplies in fiber optic cable solutions.