.jpg)

Fiber Optic Cables vs. Copper Cables: Working Principles, Performance and Cost

Introduction

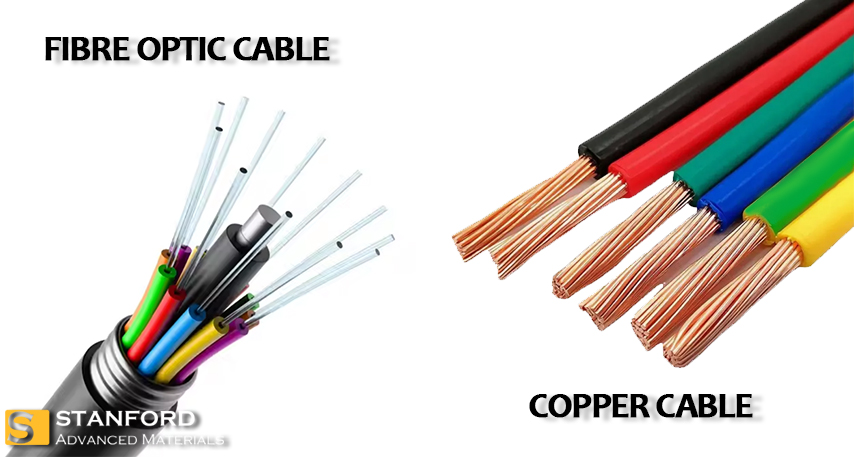

When setting up a modern network, choosing the right cabling technology is an important decision. The two main options are fiber optic cables and copper cables, each with its own advantages and drawbacks. Fiber optic cables are praised for their high performance and scalability, while copper cables remain a cost-effective choice, especially for budget-conscious projects and older systems.

This article will compare fiber optic and copper cables in terms of performance, durability, security, cost, and typical uses. Understanding these differences will help you pick the best option to meet your network's specific needs.

Working Principles: Light vs. Electricity

The core difference between fiber optic and copper cables lies in how they carry data. One uses light, the other electricity—and that distinction shapes everything from speed to signal integrity.

Fiber Optic Cables

Fiber optics transmit data as pulses of light through ultra-thin strands of glass or silica. A reflective cladding around the core keeps the light confined, allowing it to travel with minimal loss. Because light isn't affected by electromagnetic interference, this system ensures stable transmission, even in electrically noisy environments.

Copper Cables

Copper relies on electrical signals flowing through a metal conductor. Twisted pairs or coaxial configurations help reduce interference, but the signal is still vulnerable to external noise and degrades more quickly over distance. Copper works well for shorter runs and simpler setups, but its limitations are more pronounced at scale.

Key Performance Comparison

When choosing between fiber optic cables and copper cables, three key performance factors typically come into play: transmission speed, distance, and signal reliability. These characteristics are essential in determining which cable type is most suitable for specific applications. Below is a detailed comparison of the performance factors for both fiber optic and copper cables:

| Factor | Fiber Optic Cables | Copper Cables |

|---|---|---|

| Speed | Up to 100 Gbps and beyond | Typically up to 10 Gbps (e.g., Cat6a Ethernet) |

| Distance | Up to 100 km without repeaters | Effective under 100 meters |

| Signal Integrity | Immune to EMI, low noise | Susceptible to interference, higher noise |

| Attenuation | Minimal signal loss over distance | Significant loss; needs boosting for long runs |

| Durability | Resistant to heat, moisture, EMI | Sensitive to bending, corrosion, voltage spikes |

Let's break this down further:

-

Speed & Bandwidth

Fiber easily handles multi-gigabit speeds—future-ready for data center backbones, streaming platforms, and real-time control systems. Copper works well for office networks and legacy systems but tops out more quickly. -

Distance & Loss

Fiber's low attenuation means fewer repeaters, less maintenance, and better long-haul performance. Copper's signal weakens fast, especially beyond 100 meters. -

Reliability in Harsh Conditions

Fiber doesn't carry electricity, so it's safe in high-voltage areas and immune to electromagnetic noise. Copper's electrical nature leaves it exposed to EMI and ground loop issues. -

Installation Considerations

Copper is easier to terminate and install, especially for small-scale networks. But for scalability and long-term efficiency, fiber is often the smarter bet.

Cost and Application Suitability

In real-world deployment, cable selection isn't just about technical performance—it's about how well the technology fits your budget and use case. While fiber optics lead in speed and distance, copper remains relevant in many localized, cost-sensitive environments.

Upfront Cost vs. Long-Term Value

Copper cabling, especially Cat5e and Cat6, is significantly cheaper in both material and installation. It requires less specialized equipment and labor, making it a practical choice for short runs and established buildings. In contrast, fiber optic installation involves higher upfront costs due to more expensive connectors, splicing tools, and technician training. That said, fiber can offer long-term cost advantages by reducing signal loss, maintenance needs, and the frequency of upgrades.

Deployment Scenarios

| Deployment Environment | Recommended Cable | Reasoning |

|---|---|---|

| Small Office / Campus LAN | Copper (Cat6) | Affordable, easy to install, sufficient for short distances |

| Data Centers | Fiber (OM4/OS2) | High bandwidth, supports dense and long-distance links |

| FTTH / Metro Networks | Fiber | Long reach, low attenuation |

| PoE Devices (e.g., IP phones) | Copper | Enables simultaneous power and data delivery |

| Industrial / EMI Zones | Fiber | Immune to interference, safer under harsh conditions |

One advantage copper holds is Power over Ethernet (PoE) support, allowing devices to receive power and data through the same line. Fiber cannot transmit power, so if your network includes powered endpoints, separate power cables or media converters may be required.

Decision Guidance

Use fiber where high throughput, reliability, and future scalability are priorities—especially across long distances or EMI-heavy environments. Choose copper where budgets are tight, distances are short, or PoE functionality is needed. In many networks, a hybrid approach—fiber for backbone, copper for endpoints—offers the best balance.

Conclusion: Choosing the Right Cable for Your Needs

There's no one-size-fits-all answer when it comes to choosing between fiber optic and copper cabling. Each has clear strengths. Fiber offers unmatched speed, distance, and resistance to interference, making it the backbone of data centers, carrier networks, and long-haul communication. Copper remains cost-effective, familiar, and indispensable for PoE applications and short-range LANs.

What matters most is context. Evaluate your performance requirements, installation environment, future upgrade plans, and budget. In many modern networks, the smartest choice is not either/or—but both.

At Stanford Optics, we supply a full range of fiber optic cables, connectors, and compatible components, as well as legacy copper cabling solutions to support hybrid network designs. Whether you're upgrading core infrastructure or fine-tuning endpoint links, our team can help align materials with your technical and regulatory needs.

Let performance—and planning—guide the cable you choose.