What Is an Optical Fiber Preform?

1. Introduction

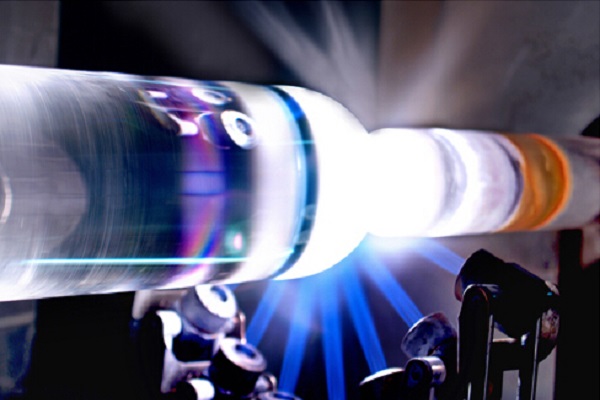

Optical fiber preforms are the starting point behind every kilometer of fiber optic cable. Though rarely seen by end users, these cylindrical glass rods serve as the base material from which high-speed optical fibers are drawn.

As global communication relies more than ever on fiber networks—from internet infrastructure to cloud data centers—the quality and structure of the preform directly shape the performance of the final fiber. Understanding the preform is key to understanding modern optical connectivity.

2. What Exactly Is an Optical Fiber Preform?

An optical fiber preform is a highly pure glass rod, typically 1 to 2 meters long, composed of two main parts:

-

Core (or rod): The center region, responsible for carrying light signals.

-

Cladding: The surrounding layer that keeps the light confined to the core through total internal reflection.

These preforms are mostly made from high-purity silica (SiO₂). Doping agents such as germanium dioxide (GeO₂) or fluorine are added to modify the refractive index, allowing precise control over optical properties.

In short: the core guides the light, and the cladding ensures the light doesn’t escape. This core-cladding structure is what gets scaled down during fiber drawing, preserving the geometry and material characteristics.

3. How Are Preforms Made?

The process of making preforms is technically demanding and involves sophisticated deposition methods. Two common routes dominate:

-

Outside Vapor Deposition (OVD): Silica particles are deposited onto a rotating ceramic rod from the outside and then consolidated into a dense glass.

-

Modified Chemical Vapor Deposition (MCVD): Reactants are introduced inside a silica tube, which is heated and rotated so layers of glass are deposited inward.

-

Vapor Axial Deposition (VAD): Builds the preform axially with soot deposition and sintering.

Each method has its advantages depending on the desired fiber type. The entire process requires ultra-clean environments, precise temperature control, and doping uniformity—all of which contribute to the final fiber’s performance, particularly in terms of attenuation and bandwidth.

4. Why Does the Preform Matter?

The preform defines nearly every optical and mechanical property of the fiber:

-

Signal attenuation: Impurities and structural defects introduced at the preform stage directly affect signal loss.

-

Transmission speed and capacity: The refractive index profile is set during preform fabrication, influencing how light pulses propagate.

-

Tensile strength and reliability: Structural uniformity and absence of microbubbles are essential for drawing strong, reliable fibers.

In other words, a high-quality preform ensures a high-performance fiber—making it a critical material in telecom manufacturing.

5. Where Are Preforms Used?

The vast majority of optical fiber preforms are used to produce communication-grade fibers, supporting:

-

Internet backbones

-

Data center interconnects

-

5G mobile networks

-

Submarine cables

Beyond telecom, preforms also serve emerging fields such as:

-

Fiber optic sensors: Used in civil engineering, oil exploration, and structural health monitoring

-

Medical devices: Specialty fibers for endoscopy, laser surgery, or photonics-based diagnostics

As fiber optics spread into more industries, demand for tailored preform designs continues to grow.

6. Conclusion

Though rarely in the spotlight, the optical fiber preform is one of the most important materials in modern communication. It defines the quality, speed, and reliability of fiber optics long before they’re installed in networks.

By understanding how preforms are made and what they impact, engineers and procurement teams can make better decisions when evaluating fiber technologies or suppliers. At the heart of every fast and stable connection lies a well-crafted preform.

Contact Stanford Optics for more informaiton.