.jpg)

A Detailed Comparison of Indoor and Outdoor Fiber Optic Cables for Modern Communication

Introduction

Fiber optic cables begin with a simple idea. A glass core and its cladding layer work together to carry light signals with efficiency. The light bounces around inside the glass core, traveling long distances without losing strength. To safeguard the delicate glass, the fibers are bundled and wrapped in a protective jacket and sometimes reinforced with extra strength material. This basic design hides a wealth of differences that help each type perform in its proper setting.

Today, our focus will be on the two common types of fiber optic systems: indoor and outdoor cables. Although both perform the essential duty of transmitting light signals, they do so in distinct ways suited to their specific environments.

Indoor Optical Cable

Indoor fiber optic cables have a simple yet reliable design. In construction, a bundle of optical fibers is first arranged into a discrete core. This core is then covered with a clear or colored plastic jacket that serves as both a protective sheath and a means of organization within a building. Because indoor cables do not contain metals, they have limited recycling potential, though they remain an economical fixture in network installations.

The design suits indoor environments well. These cables are light, flexible, and do a fine job connecting network devices like computers, switches, and servers within offices or data centers. While their tensile strength is lower than that of outdoor cables, the indoor environment rarely challenges them with extremes of moisture, temperature, or physical wear. In many modern buildings, indoor optical cables support local area networks and vertical backbone distributions with excellent performance. In addition, some indoor cables may include an extra protective layer to further guard against accidental impacts in high-traffic areas.

Outdoor Fiber Optic Cable

Outdoor fiber optic cables are built for tougher jobs. Their primary duty is to carry signals across long distances and to withstand harsh weather conditions. Like their indoor counterparts, outdoor cables start with optical fibers relying on a glass core and cladding to move light efficiently. However, the packaging is different.

The core of bundled fibers is covered by a much thicker protective jacket. Sometimes, these cables include an added metal armor within the jacket to fend off physical damage from animals, falling debris, or accidental impacts during installation. With these extra layers, outdoor cables have a greater tensile strength, an essential property when the cables are installed aerially, buried directly under the ground, or laid underwater. Their ability to resist moisture, dramatic temperature fluctuations, and mechanical stress makes them the ideal candidate for inter-building connections or long-distance installations.

Examples of outdoor applications include connections between separate office buildings in a campus, underground setups in urban streets, and even underwater connections between islands. When planning a network that stretches over open fields or urban landscapes, outdoor fiber optic cables offer the resilience and durability needed for effective communication.

Differences Between Indoor and Outdoor Fiber Optic Cables

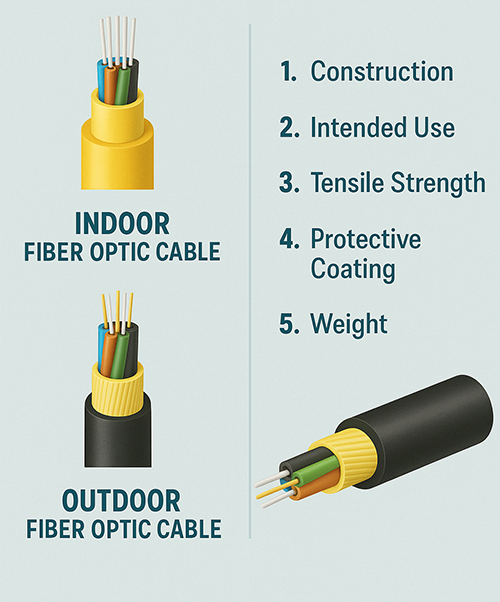

The main differences lie in construction, intended use, tensile strength, protective coating, and weight. Let us look at each point clearly:

- Construction – Indoor cables consist of optical fibers covered with a plastic sheath. They are designed to reside inside buildings. In contrast, outdoor cables are bundled more robustly and may have an additional metal armor. This design is for withstanding external pressures encountered outdoors.

- Intended Use – Indoor cables serve well to link devices within structures. They are commonly used in horizontal distribution systems that stretch across office floors or in vertical distribution among network closets and server rooms. Outdoor cables, on the other hand, are intended for inter-building links, wide area networks, or connections that need to stretch over long distances. Whether installed aerially, in conduits, or buried directly, these cables stand up to the varied environment.

- Tensile Strength – Indoor cables feature lower tensile strength because they are not expected to bear heavy loads. Outdoor cables are built tougher. Their greater strength enables them to endure the stresses placed upon them by wind, rodents, and heavy installation processes.

- Protective Coating – The protective jacket found on indoor cables is thinner. While it is enough to shield the cable inside a building, it would not survive rough outdoor conditions. Outdoor cables have a thicker and more resilient sheath, sometimes reinforced with a metal layer to provide additional protection.

- Weight – Indoor cables are lighter, a benefit when space and weight restrictions exist in controlled environments. Outdoor cables, however, are heavier. The added layers contribute to their increased weight, which is a small price to pay for improved durability in the face of environmental hazards.

Reasons for Price Differences Between Indoor and Outdoor Fiber Optic Cables

One common question is why outdoor fiber optic cables tend to cost more. The answer lies in the differences in their reinforcement materials and design choices. For indoor fiber optic cables, reinforcement is usually achieved with aramid fiber materials such as Kevlar. While Kevlar is strong, it tends to be pricier—roughly $5,000 to $6,000 per ton—and each individual fiber is protected with a nearly one-millimeter sheath. This thoughtful design contributes to a higher cost.

Outdoor cables rely on steel wires or tapes as reinforcement. This method of reinforcement in many cases simplifies the process while offering the robust protection needed outdoors. In addition, the use of single-mode fibers—which are generally more cost-effective—adds another layer of cost understanding as compared to the multi-mode fibers more often found in indoor cables. The material choices and construction methods, therefore, highlight why outdoor cables incur a higher price tag despite their apparent similarities in basic function.

Conclusion

In summary, both indoor and outdoor fiber optic cables start with the same fundamental principle—the glass core and cladding design that transports light signals. However, their differences in construction and intent are significant. Indoor cables are the go-to choice for setups within buildings, where weather and physical wear are less of a concern. In contrast, outdoor cables are made to withstand more extreme conditions, often including extra layers of metal armoring and robust jackets.

For those in need of quality materials and expert advice in fiber optic cable production, Stanford Optics is a trusted supplier that has consistently supported high-standard installations worldwide.