.jpg)

A Practical Guide to Choosing Outdoor Fiber Optic Cables

Outdoor fiber optic cables are critical for building stable, high-speed networks in real-world environments. Whether you’re linking buildings, running broadband through rural areas, or building out 5G infrastructure, choosing the right cable impacts everything from performance and maintenance to cost and reliability. This guide outlines the key cable types, explains how to match them to different use cases, and helps you make decisions based on practical needs rather than guesswork.

Why Outdoor Fiber Needs Special Treatment

Outdoor environments are tough. UV exposure, water ingress, rodents, ice, crushing pressure—cables must survive it all. Unlike indoor setups, you can’t afford to use generic or under-specified cable outdoors. The right choice reduces signal loss, prevents downtime, and avoids expensive repairs or replacements.

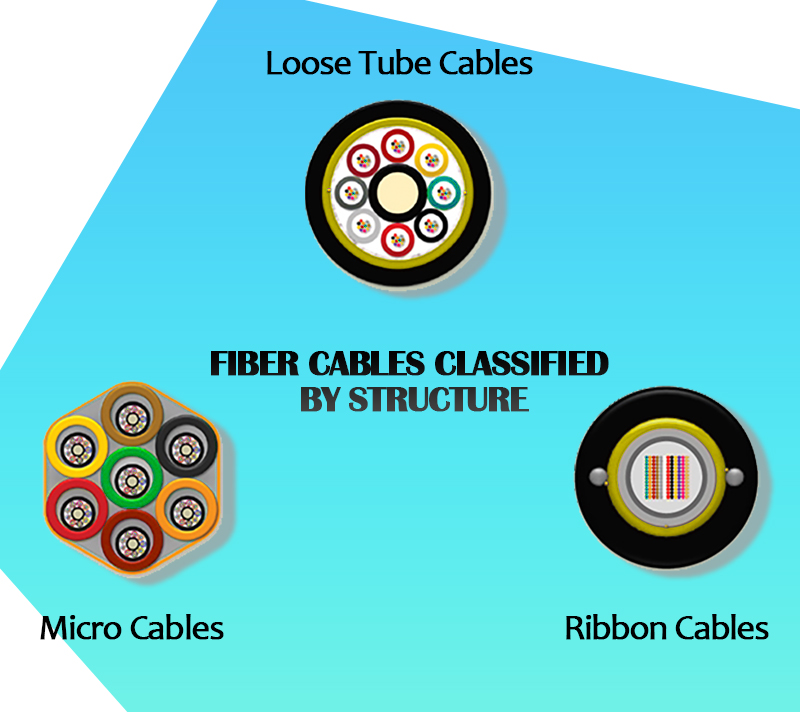

Cable Types by Physical Structure

-

-

Fibers sit loosely inside gel-filled tubes that block moisture and buffer thermal expansion.

-

Best for long-distance outdoor runs, harsh climates, or buried installations.

-

-

-

Fibers are laid out in flat ribbons that allow fast mass fusion splicing.

-

Excellent for high-count fiber networks like data centers, central offices, or metro backbones.

-

-

Micro Cables

-

Very compact and flexible, designed to fit tight ducts or microducts.

-

Useful in space-constrained areas, especially in cities or retrofits.

-

Cable Types by Installation Method

-

-

Installed on poles or messenger wires, exposed to wind, ice, and sunlight.

-

Require tensile strength and UV-resistant jackets.

-

-

-

Laid directly in soil without conduit. Must resist crushing, moisture, and rodents.

-

Use armored or water-blocked designs.

-

-

Duct Fiber Cables

-

Pulled or blown through underground conduits. Need abrasion resistance and high pull strength.

-

Easier to replace or upgrade later than direct-buried options.

-

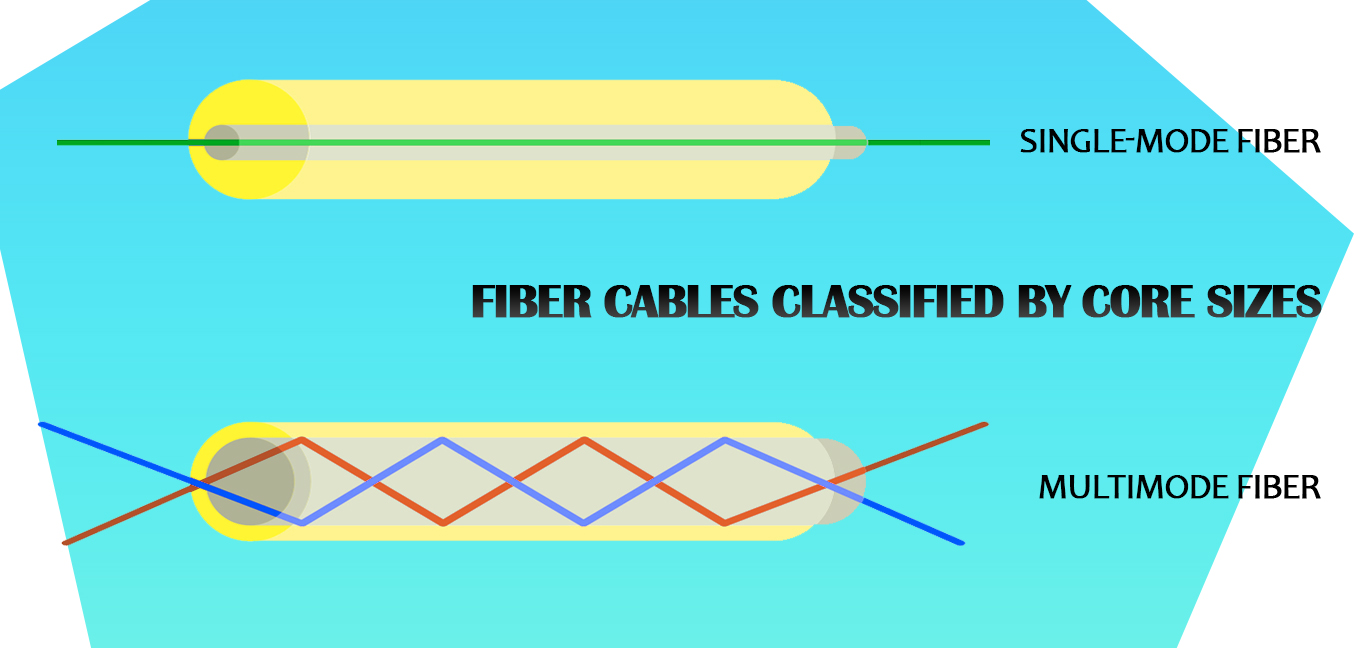

Fiber Core Types (Signal Path Differences)

-

Single-Mode (OS2)

-

Narrow 8–10 µm core carries light in a straight path with low attenuation.

-

Best for long-distance links over 10 km or high-bandwidth backbones.

-

-

Multimode (OM2 / OM3 / OM4)

-

50 or 62.5 µm cores allow multiple light paths. More signal loss but easier to terminate.

-

Suited for short links (under 500 m) like building-to-building or floor-to-floor runs.

-

Matching Cable to Application

Here’s how to align cable specs with installation needs:

| Scenario | Cable Type(s) | Why It Works |

|---|---|---|

| Long-distance link between sites | Loose Tube + OS2 | Low attenuation, gel-protected, durable |

| Data center or central hub | Ribbon + OS2 or OM4 | High fiber count and fast splicing |

| Urban deployment with limited space | Micro + Duct | Compact, flexible, ideal for microtrenching |

| Rural broadband in rough terrain | Direct Buried + Armored | Withstands crush, water, and animal threats |

| Temporary or aerial fiber run | Aerial + Loose Tube | UV-resistant with strength for sag and wind |

Practical Tips for Selecting Outdoor Fiber

-

Don’t over-spec: You don’t need armored cable in a protected conduit.

-

Plan for splicing: If mass splicing is needed, ribbon cables save time.

-

Account for future growth: Higher fiber count or duct space pays off later.

-

Check local regulations: Some installs require fire-rated jackets or specific burial depths.

-

Verify manufacturer specs: Pull strength, bend radius, and moisture protection ratings matter.

Conclusion

Outdoor fiber cabling is not a one-size-fits-all decision. The right cable depends on where it’s going, how it’s installed, and how much future flexibility you need. By understanding the real-world demands of different environments, you can avoid unnecessary costs and build a network that performs reliably for years.

Need a solution built for tough outdoor deployments? Stanford Optics provides a full range of outdoor fiber cables engineered for durability, signal integrity, and long-term stability in any environment.