The Complete Guide to MPO/MTP Systems for 400G/800G Data Centers

Let's be clear: If you're deploying 400G today or planning for 800G tomorrow, your cabling backbone will be built on MPO/MTP connectors. But getting the specifications wrong doesn't just waste budget—it locks you into an inflexible infrastructure that can't scale. Based on deployments in hyperscale clouds, here's how to navigate the three critical choices that define performance, cost, and longevity.

1. Fiber Count: It's Not Just a Number, It's Your Architecture

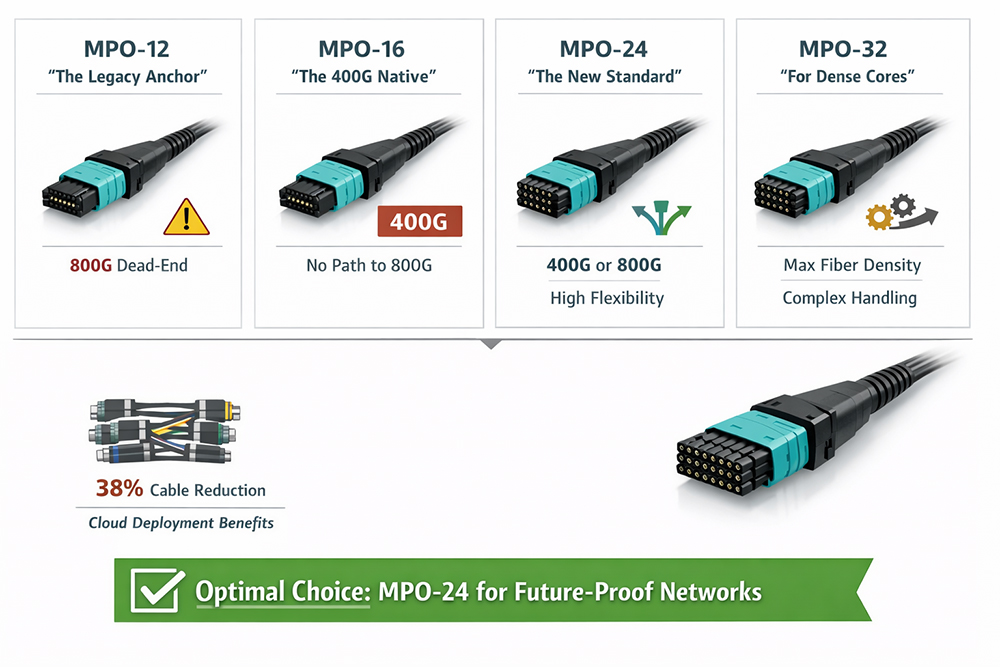

The number of fibers in an MPO connector dictates your entire network's topology and upgrade path. This is where early mistakes are made.

-

MPO-12: The Legacy Anchor. This was the standard for 40G/100G. For 400G, it can work with bidirectional (BiDi) optics, but it's a dead-end for 800G. It forces complex, inefficient cabling plants in new builds. Our advice: Avoid for new 400G spine-leaf layers.

-

MPO-16: The 400G Native. This is the minimum for standard 400G-SR8 optics, which use 8 fibers for transmit and 8 for receive. It allows a clean breakout to 4x 100G ports, which is why it's popular for migrating existing 100G clusters. However, it offers no direct path to 800G within the same trunk.

-

MPO-24: The Strategic Default for New Builds. This is becoming the new baseline. A 24-fiber trunk can support a single 800G-SR8 link (using 16 fibers) with fibers to spare, or two independent 400G-SR4 links. Its breakout flexibility to 100G or 200G is superior. The slightly higher connector cost is trivial compared to the avoided future re-cabling project.

-

Deployment Data: A major cloud provider found MPO-24 reduced total cable count by 38% in their 400G spine layer compared to an MPO-12 design, simplifying tray fill and airflow.

-

-

MPO-32: For the Densest Cores. Used when maximizing fibers per rack unit is the absolute priority, typically in core router interconnects. It introduces greater handling complexity and requires ensuring all hardware supports this density.

The Takeaway: For future-proofing, standardize on MPO-24 trunks in your main distribution areas. Use MPO-16 only if you are certain your 400G-to-100G breakout needs are fixed and long-term.

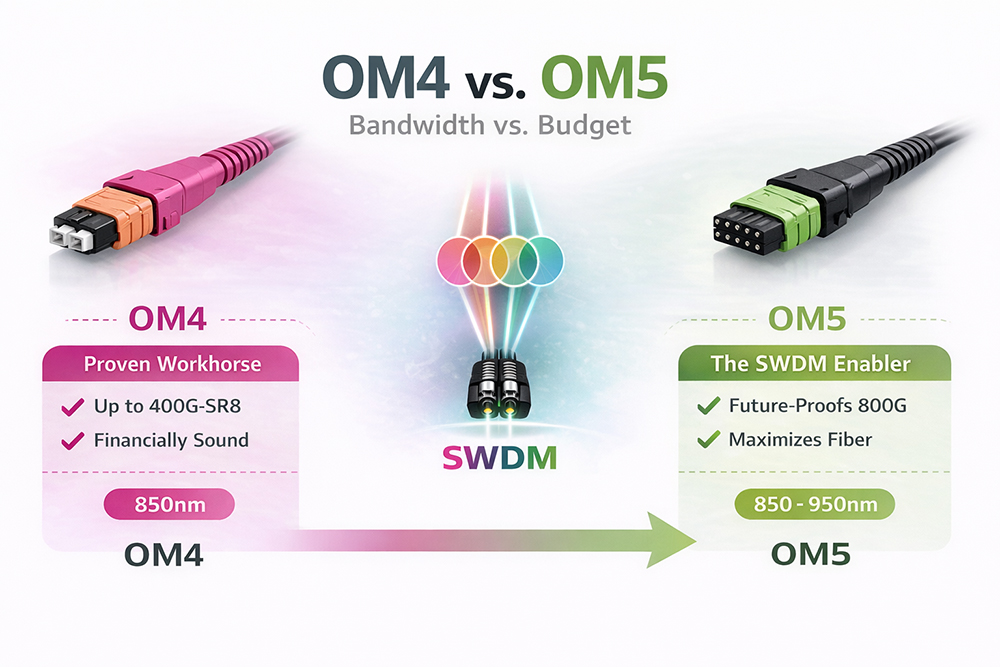

2. OM4 vs. OM5: The Bandwidth vs. Budget Calculus

This debate is often oversimplified. The choice hinges on one technology: Short-Wavelength Division Multiplexing (SWDM).

-

OM4: The Proven Workhorse. It's perfectly capable of supporting 400G-SR8 links up to 100 meters at 850nm. If your roadmap is 400G-only for the next 5+ years and your links are under 100m, OM4 is a financially sound choice. You're buying proven performance.

-

OM5: The SWDM Enabler. The "Wideband" in its name is key. OM5 is engineered to support multiple wavelengths between 850nm and 950nm. Why does this matter?

-

It Future-Proofs for 800G: 800G standards will leverage wider optics. OM5 has the modal bandwidth to support it over useful distances.

-

It Maximizes Fiber Utilization: With SWDM, you can transmit 400G over a single duplex fiber pair instead of 8 fibers. This can reclaim crucial duct space or delay new conduit builds.

-

The Cost Analysis: OM5 cable carries a ~20-30% premium over OM4. The ROI comes from saving fiber strands and extending the usable life of your cable plant. For a greenfield deployment targeting a 10-year lifecycle, OM5 is rarely the wrong choice.

-

The Verdict: If you see "800G" or "fiber exhaust" in your future planning documents, specify OM5. The incremental cost is strategic insurance.

Read more: OM1 vs OM2 vs OM3 vs OM4 vs OM5: Multimode Fiber Cable Differences

3. Polarity: The Boring Detail That Will Wreck Your Schedule

Polarity errors are the number one cause of delayed go-lives in high-density deployments. They're simple in theory but messy in practice.

-

Forget Type A and Type C for trunks. They introduce unnecessary complexity and require mixing cable types, which is a recipe for installation errors.

-

Standardize on Type B (Key-Up to Key-Down) for All Trunk Cables. This is the most robust method. A Type B trunk flipped end-to-end naturally reverses the fiber positions. This allows you to use straight-through (Type A) patch cords at both ends to connect to equipment, which are easier to source, manage, and trace.

-

Document and Enforce Your Polarity Scheme. This is non-negotiable. Your cabling vendor, installation team, and internal IT must all work from the same playbook. A single "workaround" patch cable can break the entire system's logic.

Why Pre-Termination Isn't a Luxury—It's a Necessity

Field-terminating MPO connectors are a high-skill, low-margin activity with variable results. Factory pre-termination solves this:

-

Loss Budget Certainty: Every connector is polished and tested to a guaranteed standard (typically <0.35 dB), giving you a reliable, consistent loss budget for your 400G/800G links, which have tighter tolerances than ever.

-

Eliminate Cleanliness as a Variable: Factory-sealed connectors arrive ready. You remove the largest source of link flapping and performance issues from day one.

-

Speed: Deployment is literally "unroll and plug." A team can deploy hundreds of trunks in the time it takes to field-terminate a dozen.

Building Your System: Integration is Everything

The final step is moving from components to a system. This means ensuring your MPO trunks, breakout harnesses, and patch panels are designed to work together. Look for a partner that provides:

-

Clear System Diagrams for common architectures (spine-to-leaf, etc.).

-

Pre-configured Kits that bundle compatible components, eliminating guesswork.

-

Expert Support to validate your design before the order is placed.

Your Next Step:

Stop comparing datasheets and start modeling scenarios. The right choice depends on your specific distances, rack layout, and upgrade timeline.

Ready to design your 400G/800G cabling infrastructure with confidence?

Contact Stanford Optics to receive our comprehensive design guide and access to an online configurator tool that generates compliant, optimized bills of materials for your specific rack layout and bandwidth roadmap.

.jpg)