Protecting Backbone Networks: A Guide to Fire, Rodent & Corrosion Resistant Cables

Backbone fiber networks are like the circulatory system of modern communications. When these networks fail, regions can lose service, businesses halt, and emergency responses may be delayed. In busy traffic tunnels, coastal areas, and industrial sites, standard cable designs often fall short. They are not built to withstand dangers such as fire, rodent damage, and chemical attack. Using specially designed cables with extra layers of protection is a smart way to keep these networks running securely for decades.

This article discusses simple ways to protect backbone cables. It looks at protective jackets that lower smoke production during fires, physical layers that keep pests away, and special sheaths that resist chemicals. Using these methods is like putting an insurance policy on the most critical parts of a network.

The Non-Negotiable Need for Reliability

An outage in the backbone network is much more than a minor inconvenience. When a cable fails, it can freeze entire regions, disrupt financial systems, and even delay emergency responses. This cost is measured in millions of dollars per hour. While extra equipment and backup paths help, the physical cable itself is often the weakest point. Ensuring "25-year+" reliability in these scenarios requires moving beyond generic outdoor cable to specialized, defense-in-depth designs that proactively combat fire, biological, and chemical threats. This is not an over-engineering expense; it is a calculated insurance policy for the network's most vulnerable physical segments.

Three Key Protection Technologies

LSZH Cables for Fire Safety

Fires in enclosed spaces such as railway tunnels and data centers can cause thick smoke and harmful gases. Traditional cable coverings made from standard materials often release dangerous chemicals when burned. These substances not only block exits but also harm sensitive equipment nearby.

The Solution

Cables with LSZH (Low-Smoke Zero-Halogen) jacketing. These materials are formulated to:

- Minimize Smoke Emission: Produce dramatically less opaque smoke, maintaining visibility for evacuation and firefighting.

- Eliminate Corrosive Gases: Avoid releasing acidic halogen gases (like HCl) that can destroy sensitive electronic equipment far from the fire source.

- Standard Compliance: They are specified for enclosed public spaces by standards such as IEC 60332-1 (Flame Retardant) and IEC 61034 (Low Smoke).

Anti-Rodent & Anti-Termite Cable

In areas with farms, heavy industry, or near coastal shores, rodents and termites can chew through cables. Much like how an iron tool left outside will rust, a cable worn by pests will fail sooner. The mechanical protection needed must resist this kind of attack.

The Solution

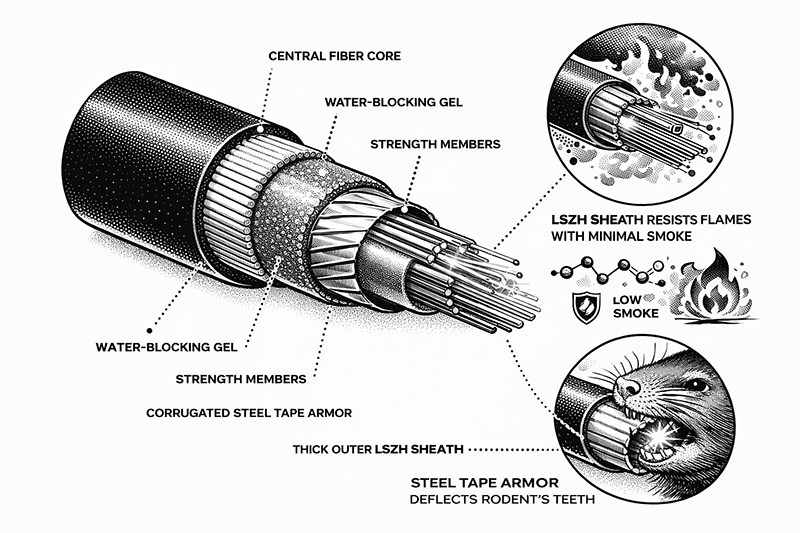

A multi-layered defense:

- Mechanical Armor: A primary layer of corrugated steel tape (CST) or hard stainless steel wire armor provides a physical barrier that is virtually impenetrable to rodents.

- Chemical Repellent Sheath: For a less rigid solution, cables can be sheathed in a specially formulated polymer (e.g., nylon-12) infused with non-toxic, bittering agents like capsaicin. This forms a durable, abhorrent barrier that effectively deters rodents from gnawing. More importantly, it does not harm animals or the environment.

Cables for Chemical & Corrosive Environments

Cables placed in or near chemical plants, fertilized fields, or salty offshore environments face constant attacks from corrosive agents. Chemicals, acids and salts can weaken a cable over time, much like metal left in damp conditions rusts away.

The Solution

Advanced sheathing materials and protective designs:

- Barrier Sheaths: Utilization of Polyethylene (PE) with high density and specific formulations offers excellent resistance to a wide range of chemicals and moisture.

- Armor Protection: For steel armor used in direct burial, ensuring it is galvanized or coated with a robust polymer is critical to prevent rust. In highly corrosive environments, stainless steel armor (e.g., 304, 316 grades) is the premium, maintenance-free choice.

Standards and Compliance

Specifying special protection cables requires demanding objective proof. Key international standards serve as the baseline for performance:

- Fire Safety: IEC 60332-3 (Flame spread for bunched cables), IEC 60754 (Halogen acid gas test).

- Rodent Resistance: IEEE 1202 / UL 44 include tests for cable damage by cable-chewing rodents.

- Corrosion & Environmental: IEC 60794 (Generic specification for optical fibre cables) includes tests for water penetration, corrosion resistance, and environmental conditioning. ISO 9227 (Salt spray tests) validates anti-corrosion performance.

A credible manufacturer like Stanford Optics should provide clear test reports demonstrating compliance with these relevant standards for their specialty cable products.

Case Study: Solving Coastal Network Failures

A national operator once faced repeated cable failures along a coastal backbone route. Rodent damage and saltwater exposure led to high maintenance and unpredictable service. In response, the operator tried a new system based on special cable designs.

The new approach used:

- A rodent-proof layer of corrugated steel tape that stopped any chewing attempts by small animals.

- A chemical-resistant outer cover crafted from high-density polyethylene. This sheath prevented the damaging effects of saltwater and chemicals.

- Metal parts coated with a heavy-duty anti-corrosion layer, ensuring the cable stayed strong throughout the season.

After three years of careful monitoring, the results were clear. Damage from rodent bites dropped by over 95 percent, and corrosion issues vanished entirely. The improved cable design transformed a difficult coastal route into a reliable network segment.

Conclusion: Investing in Long-Term Network Assets

The cost of a backbone cable is not just what you pay for a meter. It is the total cost over many years of keeping critical communication lines open and reliable. Investing in cables with robust protection against fire, pests and chemicals is wise. It avoids the staggering costs of emergency repairs, service shutdowns, and economic harm.

When planning network designs in high-risk areas, it pays to talk with seasoned experts. A careful assessment of an installation environment and the risks involved can lead to tailored solutions that ensure lasting performance.

For those who need dependable materials and expert advice, Stanford Optics stands ready as a trusted supplier. Their products have helped many operators safeguard their network's critical segments. Reaching out to them for a consultation can represent the first step toward securing a network that stands the test of time.

Does your backbone network have vulnerable segments exposed to fire, pest, or corrosion risks?

Reach out to Stanford Optics for a confidential consultation. Our engineers will help you analyze your specific route threats and recommend the most cost-effective, compliant specialty cable solution to ensure your network's lifeline remains intact for decades.

.jpg)