Data Center Cabling: Balancing Performance & Cost from Trunk to Patch

Abstract: Building a data center is an exercise in brutal efficiency: every watt, every square foot, and every millisecond counts. Yet, the cabling that ties it all together is often an afterthought, treated as a commodity. This is a costly mistake. The architecture—from the spine (trunk) down to the leaf (patch)—demands different solutions. This guide breaks down the cabling strategy by layer, explaining why a trunk is more than just a thick patch cable and why using OM5 everywhere is a financial mistake. We'll provide a clear selection framework to optimize both performance and cost.

Why One Cable Type Doesn't Fit All

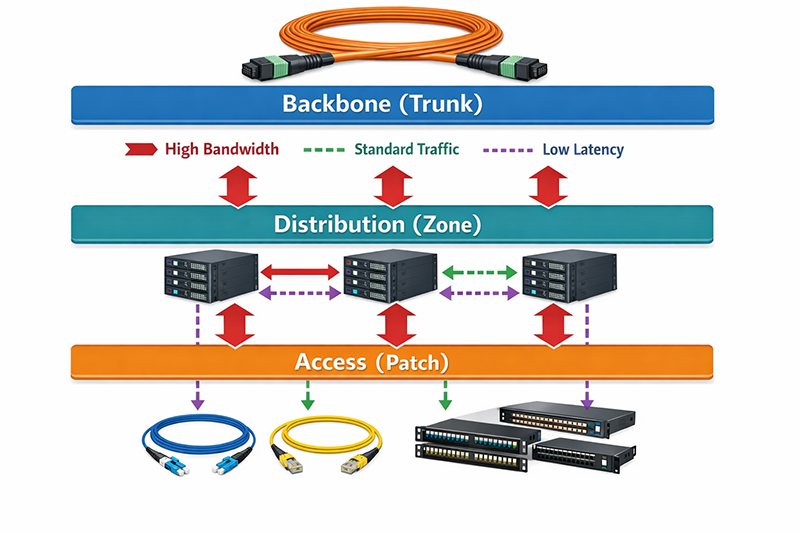

Data center cabling isn't a homogenous web; it's a structured hierarchy with three distinct physical and performance layers:

-

The Backbone (Trunk / Cross-Connect): This is your data center's central nervous system. It connects major distribution areas (MDAs) to equipment distribution areas (EDAs). Traffic here is aggregated, massive, and relatively static once deployed. The mandate is maximum density, ultimate reliability, and future-proofing. These links are "set and forget" for years.

-

The Distribution Zone (EDA / Zone Cabling): This is the circulatory system, distributing from the spine to the racks. It requires a balance of density and some flexibility for reconfiguration as racks are populated.

-

The Leaf Layer (Intra-Rack Patch): This is the peripheral nervous system—the final, dynamic connection to the server. Here, the environment is chaotic: constant flexing, repeated mating/unmating, tight bends around cable managers. The mandate is extreme flexibility, durability, and space efficiency.

Confusing the requirements of one layer with another leads to overspend, underperformance, or operational headaches.

Trunk Cable Selection

Selecting trunk cable is a capital expenditure decision. Think of it as laying down network "highways." You're not just buying for today's 100G; you're building the conduit for 400G and 800G. Here's the checklist:

-

High Fiber Count & Ultra-High Density: Deploying 864-fiber cables is cheaper per fiber and uses far less conduit space than multiple 144-fiber cables. Density is a direct real estate saving.

-

Pre-termination is Non-Negotiable: Field-terminating hundreds of fibers is a reliability and labor-cost nightmare. Factory-terminated MPO/MTP trunks with documented IL/RL performance guarantee plug-and-play reliability and slash deployment time from days to hours.

-

The Upgrade Path is in the Fiber: For new builds, OM4 is the sensible minimum, OM5 is the strategic choice. OM5's extended bandwidth for Short Wavelength Division Multiplexing (SWDM) allows you to run 400G over a single pair of fibers over longer distances, effectively future-proofing your fiber plant. It's not about needing OM5 today; it's about having the option tomorrow without re-cabling.

Patch Cable Selection

Patch cables are the "toolkit" for your technicians. They get handled, swapped, and bent daily. Performance here is about surviving the environment.

-

Bend-Insensitivity is Mandatory: Bend-Insensitive Fiber (BIF) technology in patch cables allows tight, stack-saving bends without light loss, preventing "macro-bending" attenuation that kills a link.

-

Durability = MTBF: Look for features that combat the daily grind: robust, snag-free boots that protect the ferrule, flexible, low-compression jacketing that withstands thousands of flex cycles, and high-quality zirconia ferrules that maintain alignment after hundreds of matings.

-

The Space Saver: Ultra-Slim Patch Cables: Replacing standard 2.0mm or 3.0mm patch cords with 1.6mm or even 1.2mm ultra-slim cables can increase tray capacity by 50% or more. This isn't a minor improvement; it's the difference between a tidy, manageable rack and an impenetrable nest that blocks airflow and makes changes impossible.

-

Cleanability is a Feature, Not a Bonus: The connector end-face is the number one cause of link failure. Choose patch cables with retractable dust caps and consider angled physical contact (APC) polished connectors for particularly sensitive laser-based links (like DWDM), as they are less prone to back-reflection and contamination issues.

The Cost-Benefit Blueprint

Deploying OM5 or ultra-slim cables everywhere torches your budget. A smart architect tiers the solution:

| Cabling Layer | Performance Goal | Recommended Solution | Cost-Saving Rationale |

|---|---|---|---|

| Long-Haul Trunk (Between Buildings/Flows) | Max distance, future upgrade path | Single-mode OS2 | The only choice for >500m. Unlimited bandwidth for any future standard. |

| Intra-Data Center Trunk (MDA to EDA) | High density, 400G/800G readiness | OM5 Pre-terminated MPO Trunk | OM5 enables SWDM, allowing higher speeds over fewer fibers, reducing overall fiber count and optics cost over time. |

| High-Density Zone (To top-of-rack switches) | Balance of performance & flexibility | OM4 Pre-terminated Trunk / Harnesses | For links under 100m, OM4 supports all current 100G/400G standards (via SR4) at a lower cost than OM5. |

| Intra-Rack Patch | Flexibility, durability, space saving | OM4 Ultra-Slim Bend-Insensitive Patch | OM4 is more than sufficient for <5m server connections. Ultra-slim design maximizes airflow and manageability. |

The Stanford Optics Take: Our role is to provide the right material for each layer. We don't just sell fiber; we provide the pre-terminated OM5 trunk that secures your upgrade path and the ultra-slim, ruggedized OM4 patch cable that survives your data hall. It's about engineering the entire ecosystem for total cost of ownership.

Ready to optimize your data center cabling architecture?

Contact Stanford Optics for a free, layer-by-layer consultation. Our engineers will review your floor plan and traffic requirements, and provide a tailored product sample kit—from trunk to patch—so you can test fit and performance in your own environment.

.jpg)