Optical Hybrid Cables: A Comprehensive Guide

Networks today need more than bandwidth. Devices deployed at the network edge—a 5G radio, a security camera, or an industrial sensor—require high-speed data connectivity and power. It is technically possible to have a separate fiber and electrical cable, but it adds complexity, cost, and maintenance overhead.

Optical hybrid cables address this challenge directly. By combining optical fibers and copper conductors under a shared sheath, they carry communication and power simultaneously. Combining them in this manner makes installation easier, reduces cabling density, and provides a more stable infrastructure.

What is a Hybrid Cable?

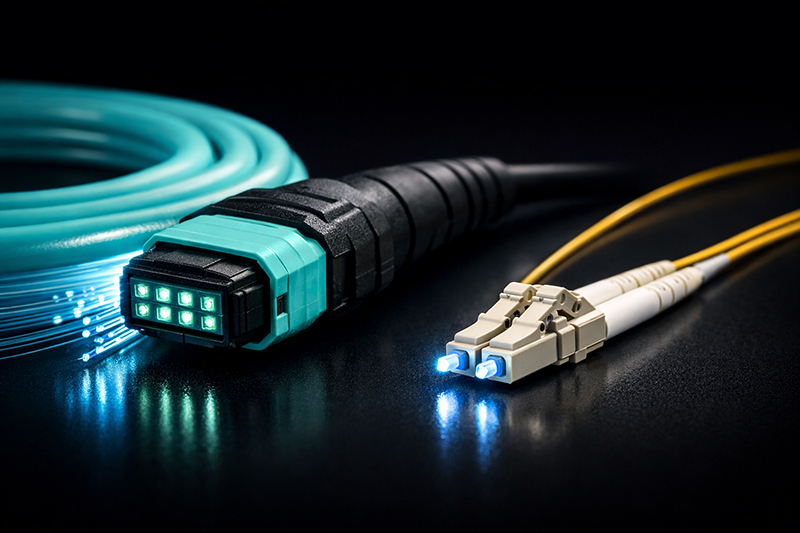

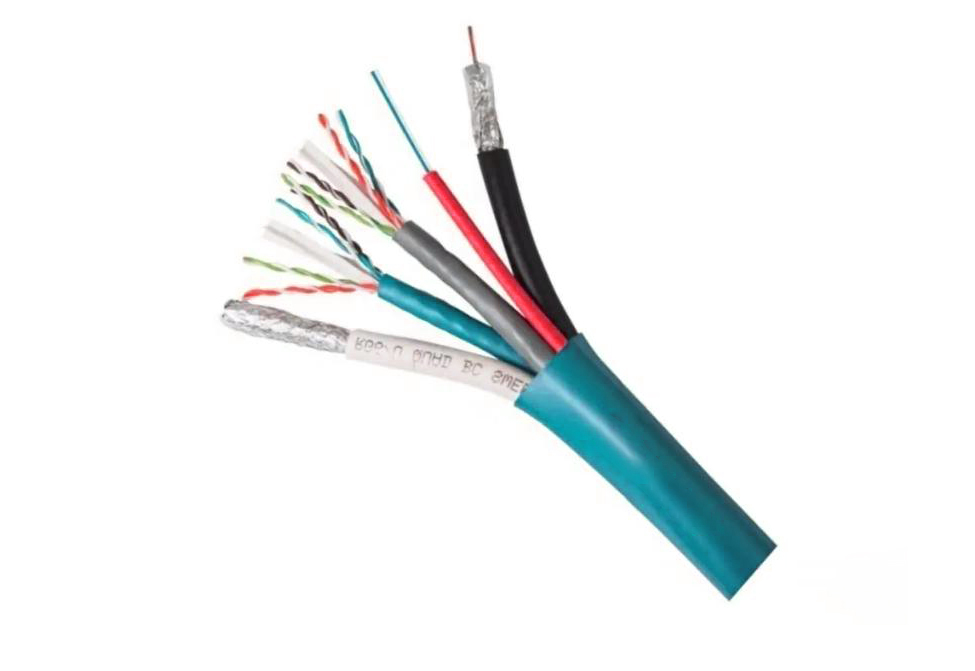

A hybrid cable combines two transmission media:

- Optical fibers for data, typically single-mode or multimode.

- Copper power conductors, usually low-voltage DC to supply the kind of device used in remote radios or IP cameras.

This is different from a composite cable, where many similar elements are brought together in one assembly (such as multiple fibers together). Hybrids are specifically configured to bring together several functions in a single assembly.

The physical construction typically includes:

- Individual compartments or closely buffered layers to separate copper and fiber.

- Shielding to reduce electromagnetic interference.

- Armored jackets or waterproof layers for harsh environments.

Advantages of Hybrid Cables

3.1 Both Data and Power in One Cable

The key benefit is consolidation. Instead of installing two or three separate cables, installers require only one. This eases mess, speeds deployment, and minimizes failure points.

3.2 PoE and Remote Power Support

Most equipment is reliant on Power over Ethernet (PoE) or similar DC power. Hybrid cables permit this directly, with a single cable being able to support both the fiber backhaul and the power to power cameras, Wi-Fi APs, or VoIP phones.

3.3 Endurance in Extreme Environments

Hybrid cables are usually built for industrial or outside service. Armored varieties are rodent and crush resistant. UV-resistant jackets withstand long-term sunlight exposure. Temperature ratings allow for use in hot and freezing conditions.

3.4 Cost and Efficiency

Assuming hybrids could cost more per meter than conventional fiber, overall project expense is usually lower:

- Fewer individual cable runs.

- Less conduit space.

- Less termination hardware.

- Easier installation and maintenance.

Read more: Technical Advantages of High-Performance Optical Hybrid Cables

Technical Considerations

4.1 Fiber Types

- Single-mode (OS1/OS2): Long backbones, low loss, telecom standard.

- Multimode (OM3/OM4/OM5): Shorter distances, high bandwidth, usually used within campuses or factories.

4.2 Conductor Options

- Copper gauge (18 AWG, 16 AWG, 14 AWG) determines the highest current capacity.

- Voltage rating is usually 48 V DC or less for network devices.

- Oversizing is wasteful of cost; undersizing may result in overheating.

4.3 Shielding and Encapsulation

- Foil or braid shielding eliminates electromagnetic interference.

- Double-layered parkas and waterproof gels for outdoor or buried installations.

4.4 Standards and Compliance

To ensure interoperability and safety, hybrid cables may comply with:

- IEC 60794 – optical fiber cable standards.

- TIA/EIA 568 – structured cabling standards.

- IEEE 802.3af/at/bt – PoE specifications.

- RoHS/REACH – environmental standards.

Applications

Telecom Networks

5.1 Telecom and 5G Networks

Hybrid cables are employed in fiber-to-the-antenna (FTTA) systems. Cell tower remote radio units need to transfer data through optical fiber and power through copper. Hybrid use minimizes tower cabling and weight. As 5G technology small cells continue to expand in cities, the hybrid cable efficiency is even more important.

5.2 Surveillance Systems

IP cameras require power and high-speed data. Hybrid cabling avoids the need for running a discrete copper line, especially in large campuses, transportation terminals, and the outdoors.

5.3 Industrial Automation

There are hundreds of sensors, controllers, and robots employed by factories. Hybrid cables provide data and low-voltage power, which reduces wiring complexity on already congested control rooms and manufacturing floors.

5.4 Renewable Energy

In solar or wind farms, hybrids can connect inverters, monitoring stations, and sensors, transmitting data as well as auxiliary power. Their power is most useful in outdoor, elongated configurations.

Installation and Maintenance

6.1 Installation Steps

- Site Evaluation – Measure distance, device power requirement, and surrounding conditions.

- Cable Choice – Choose fiber type, copper gauge, and shielding based on the application.

- Routing – Create routes without sharp bends, crushing hazards, or high EMI areas.

- Termination – Use the right fiber (LC, SC, etc.) and copper terminations.

- Testing – Optically test loss, OTDR traces, and power transfer before it goes into service.

6.2 Maintenance Practices

- Inspection: Check for abrasion, water intrusion, or rodent damage.

- Monitoring: Use diagnostic tools for the optical signal level and electrical load.

- Connector maintenance: Clean fiber connectors and check copper terminations regularly.

- Redundancy: Critical networks often employ dual-path cabling to avoid downtime.

Common Problems and Solutions

- Signal Interference: Use shielded cable and proper grounding.

- Overheating Conductors: Avoid excess current in excess of rated load.

- Connector Failures: Use quality material and qualified technicians on termination.

- Physical Damage: In outdoor environments, armored cables protect cables against crushing and chewing.

Comparison with Alternatives

| Feature | Separate Fiber + Copper | Composite Cable | Hybrid Cable |

|---|---|---|---|

| Cable count | Two or more | One, same medium | One, mixed media |

| Installation cost | High | Medium | Low overall |

| Functionality | Data and power separate | Data only | Data + power |

| Best use case | Legacy networks | High fiber density | Modern integrated networks |

Conclusion

Optical hybrid cables offer a simple solution to an expanding issue: how to transmit bandwidth and power with efficiency. Their advantages are lower installation effort, cost savings, and higher reliability. From telephone towers to factory floors and renewable energy farms, they are fast becoming a go-to tool for contemporary infrastructure.

For network designers, installers, and users, hybrid cables are not just a convenience but a strategic choice that provides scalable, reliable, and future-proven systems.

Stanford Optics develops high-quality fiber optic hybrid cables to meet the diverse needs of modern industries. Our GDTA access network fiber optic hybrid cables feature a dual-layer precision steel armor design, effectively resisting mechanical stress and physical damage. This design enhances the cable's tensile and compressive strength, ensuring stable long-distance transmission, especially suitable for complex environments.